Technical Details

Martin Sluka sent me this stop bobbin in 2024. He made it around 1985.

My Sluka - Stibrányi is 202 mm. tall, 64 mm. wide, 32 mm. thick, and weighs 326 g.

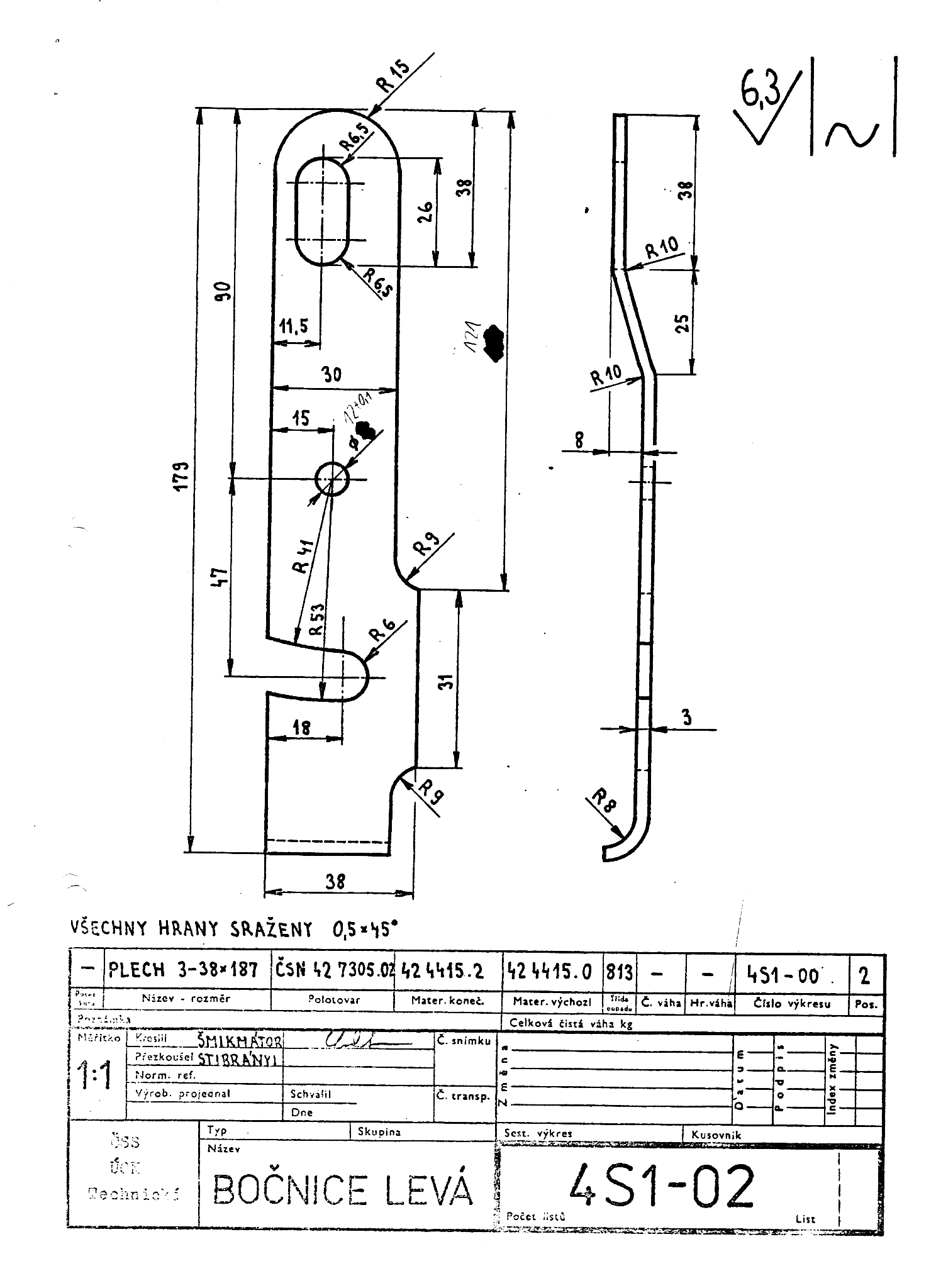

The two side plates are made of 2.9 mm. aluminum. One side plate pivots to allow threading the rope. The upper ends of the side plates are bent toward each other to hold the rope in place when the device is closed. The lower ends of the side plates are bent to converge at the attachment point, which consists of a 14 mm. wide, 30 mm. high hole on the fixed plate and a matching hook on the other. The upper portion of the hook is covered by a stamped gate. The gate pivots on a steel rivet, and a spring closes the gate.

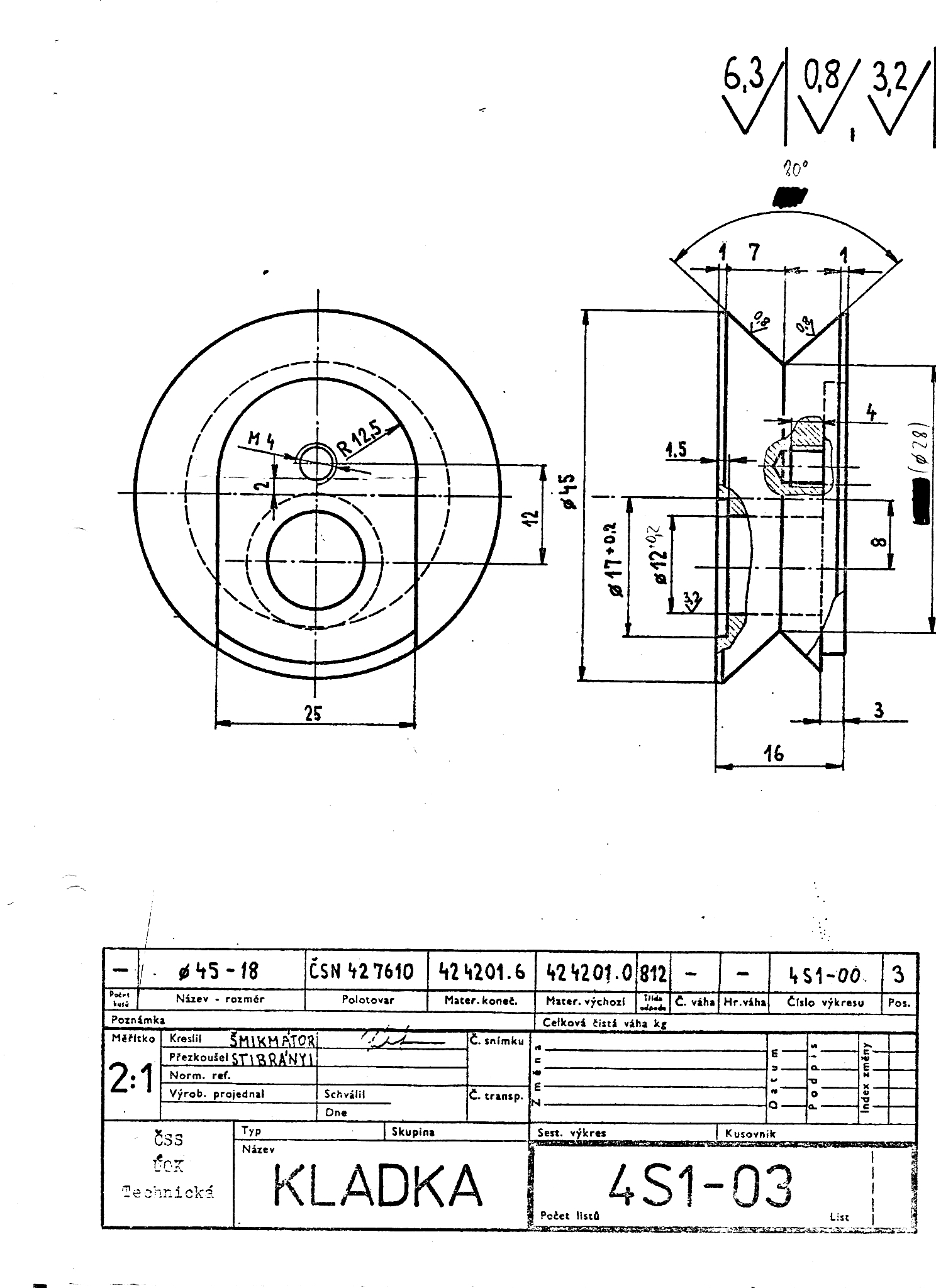

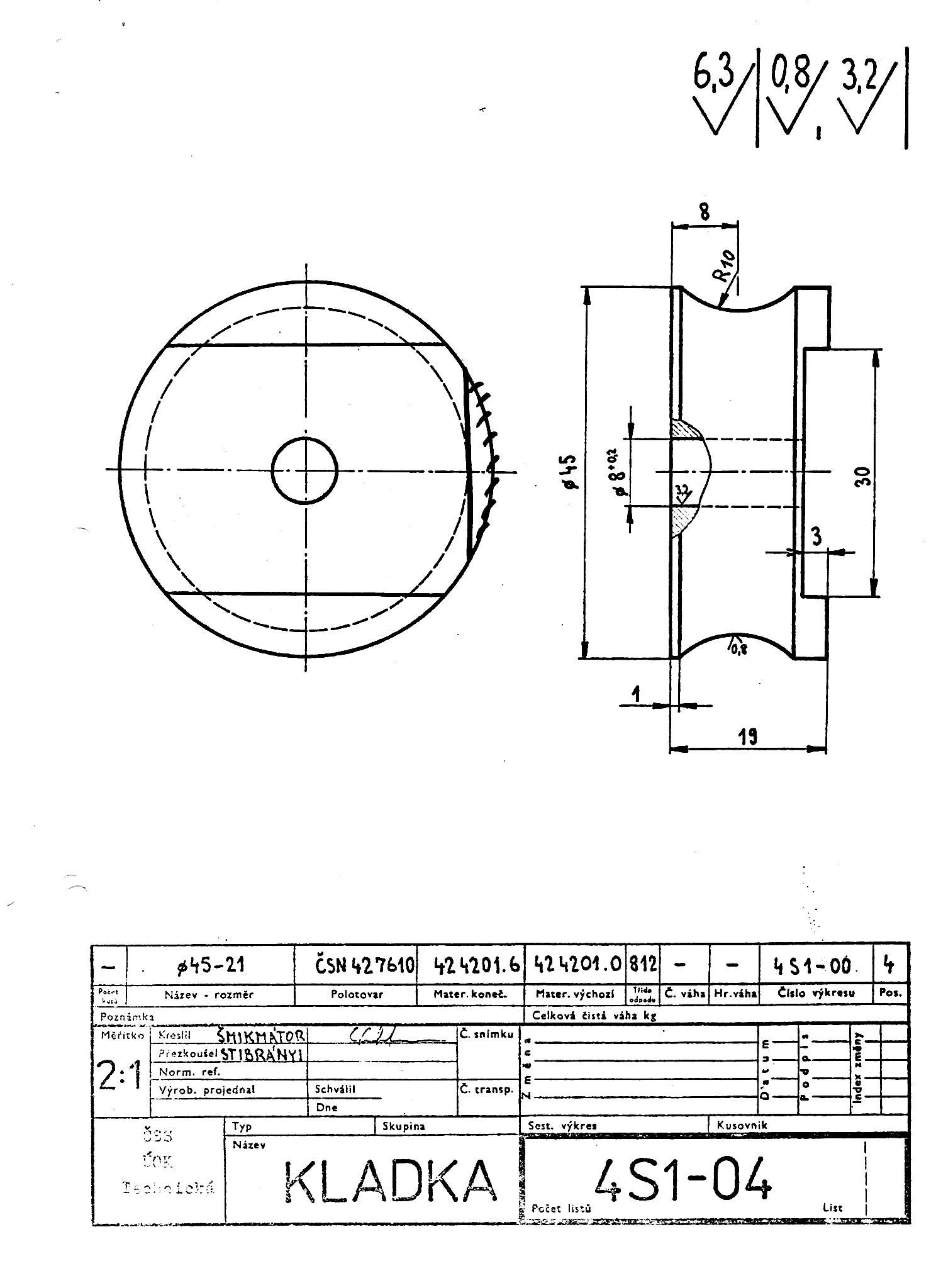

The bollards are turned from titanium alloy. Each is 45 mm. in diameter. The upper one is 16.1 mm. thick. The upper bollard is part of an autostop assembly. The periphery has a V-shaped groove with a 31.8 mm. minor diameter and a 3.2 mm-wide flat base. There are two mild flats on the periphery. One facilitates rigging by providing clearance for the rope, and the other allows the upper bollard to close more closely with the lower bollard.

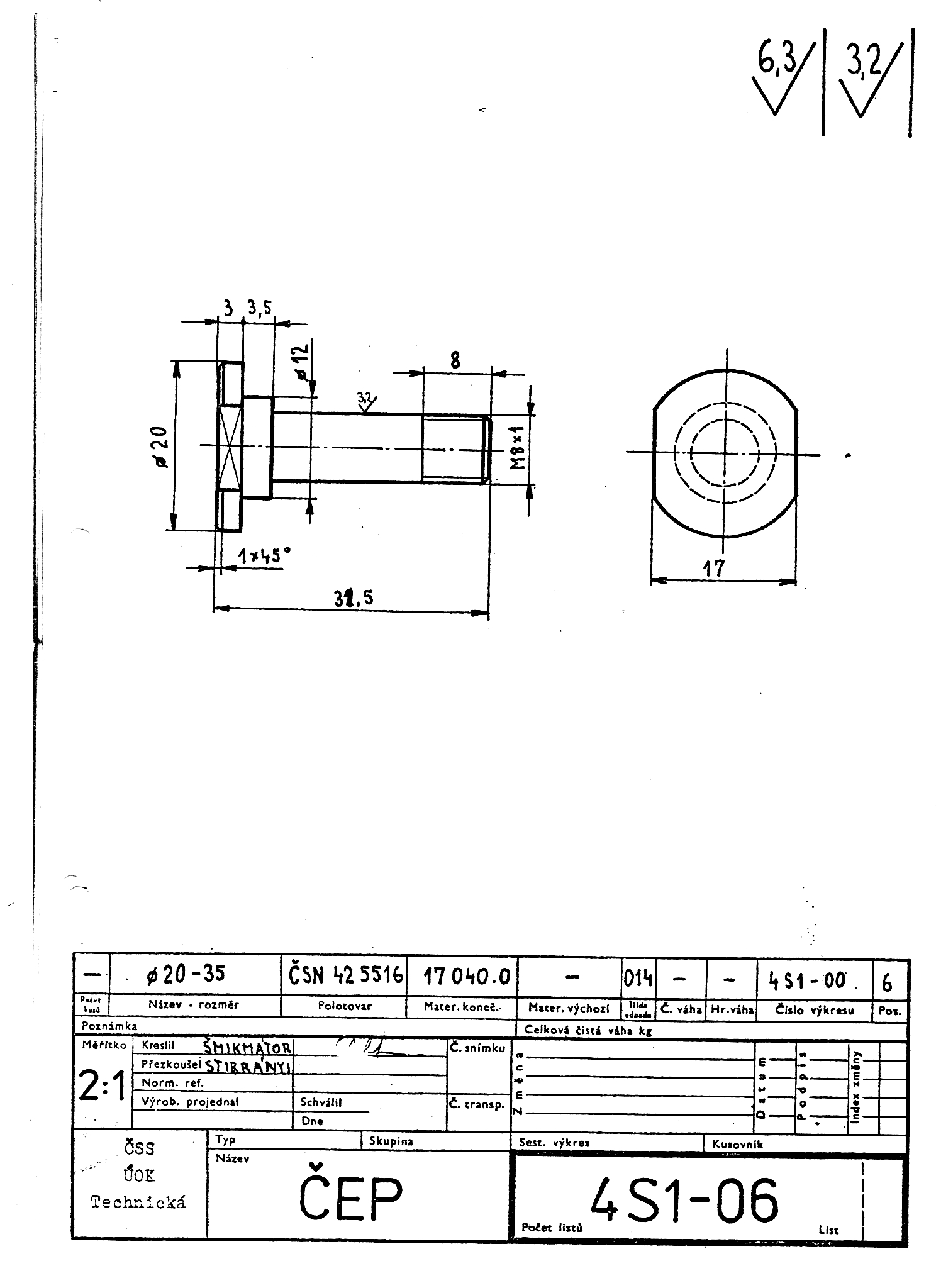

An aluminum handle is attached to the fixed side plate side of the upper bollard, presumably with one or more hidden screws. The bollard and handle assembly rotate on the upper shoulder bolt. The bollard is eccentrically-mounted on the bolt. Friction from the main rope’s passage tends to turn the bollard and force the it towards the lower bollard, thus locking the rope and ideally arresting the descent. The rappeller uses the handle to keep the autostop feature disengaged.

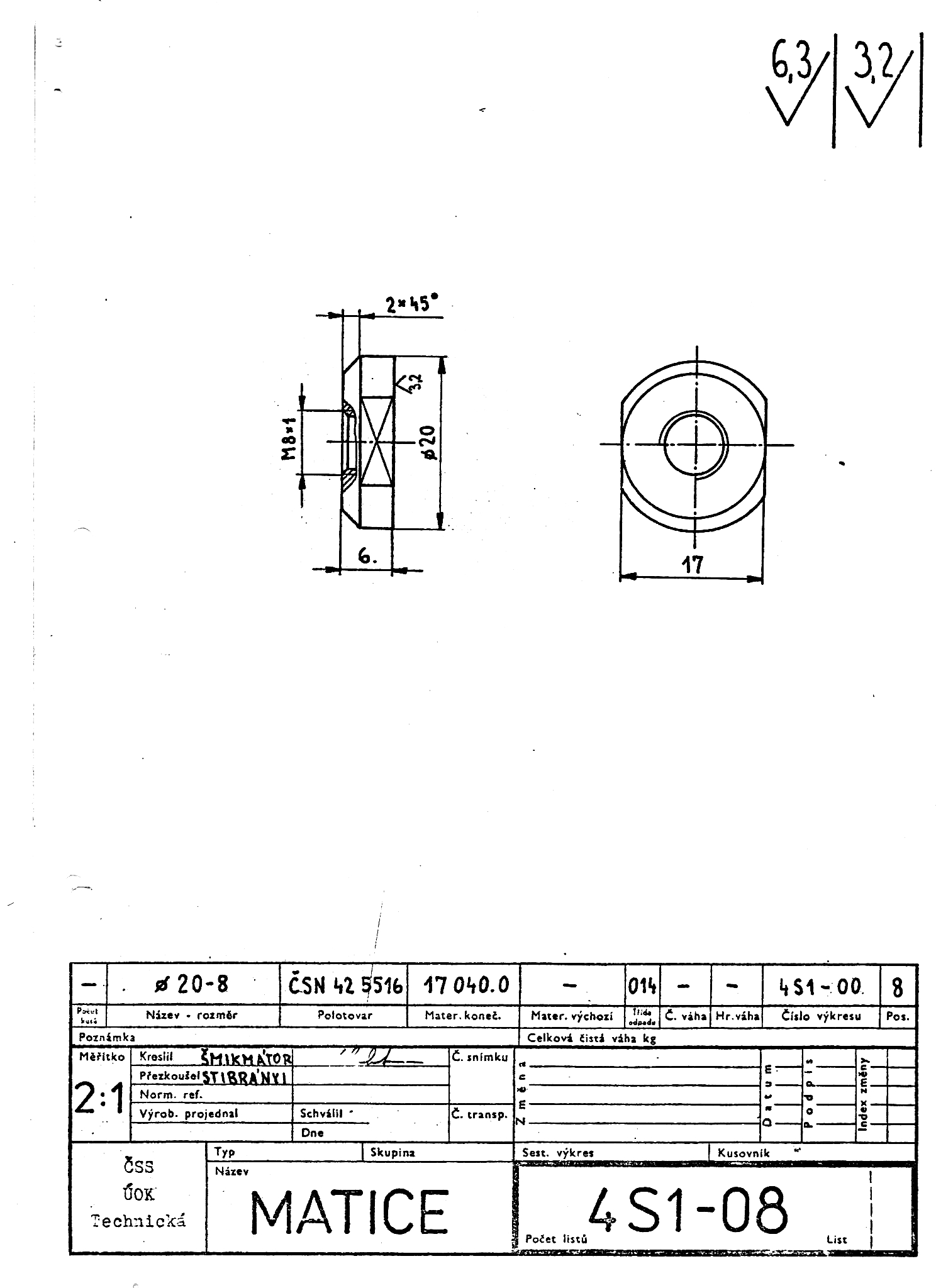

The lower bollard is 17 mm. thick. The increased thickness allows for a milled slot to keep it from rotating on the fixed side plate. The bollard is bolted to the fixed side plate with an 8 mm. bolt and a shoulder nut. The pivoting side plate pivots on the lower shoulder nut and has a slot to fits a groove in the upper bolt's head. The lower bollard has a 3 mm. deep U-shaped rope groove.

Martin made this bobbin in the mid-1980s following a published drawing. Gustáv Stibrányi, a Hungarian national living in Slovakia, originated this stop bobbin design, probably in the late 1970s. Martin’s is a left-handed version, while the photos I've seen of Stibrányi's show a right-handed bobbin.

Martin described the titanium bollards as a " quite crazy idea because titanium is bad distributor of heat." Thermal characteristics aside, the titanium wears well. Martin used this bobbin for many years, and there is still no significant wear on the bollards.

Unlike the traditional Petzl Stop, it is the upper bollard on the Stibrányi that rotates. Simple physics shows that the rope produces less torque on the upper bollard than on the lower one. All other things being equal, which they never are, using the upper bollard as the stop provides less autostop action. Is it enough? That depends on the rope you are using and how heavy you are. I see significant potential for varying the performance of the Stibrányi design by varying the bollard spacing, the offset mounting the upper bollard, and the handle mounting angle.

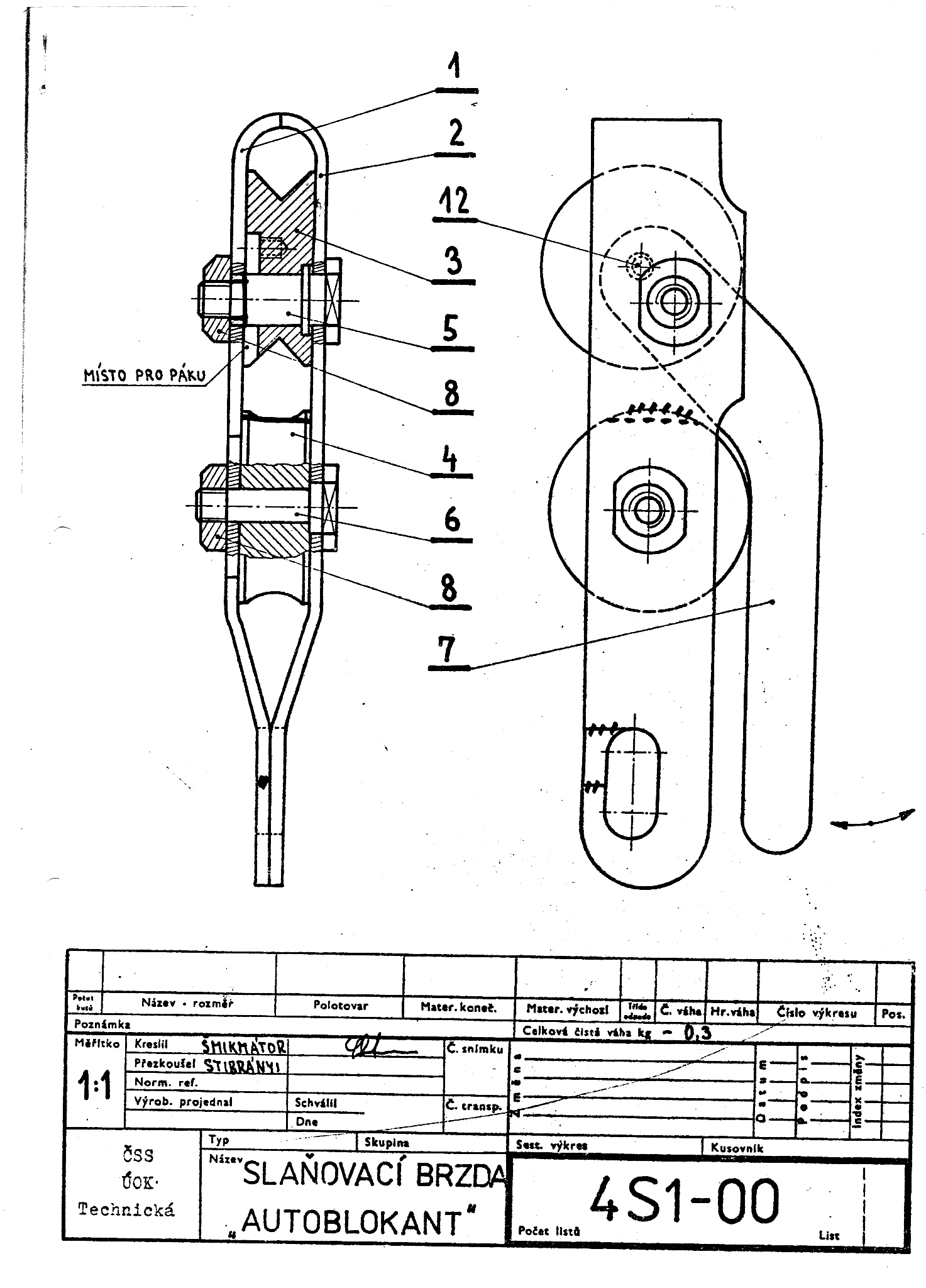

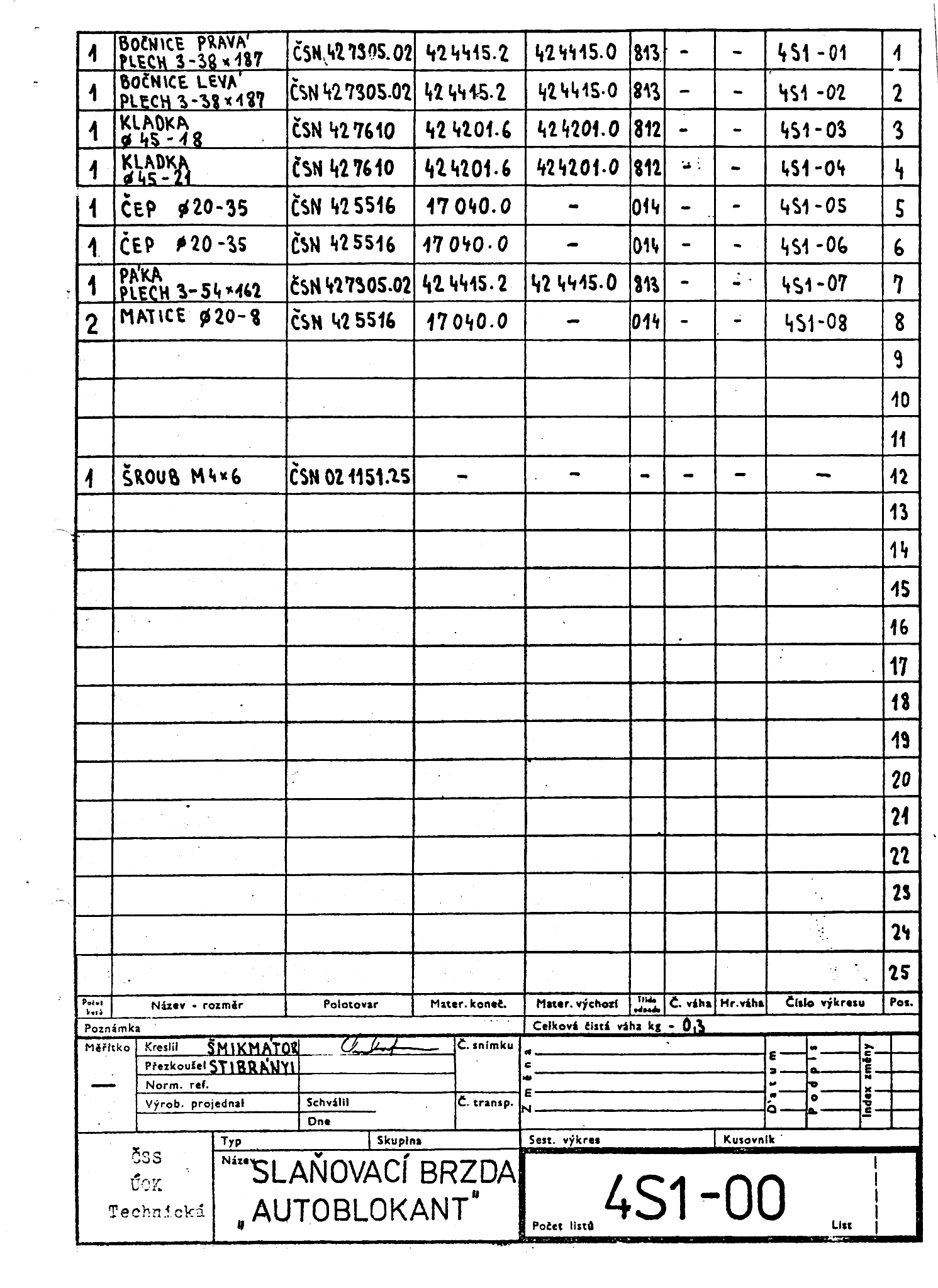

Martin sent me the following drawings from the Technical Commission of Czech Speleological Society. Their date is uncertain, but we believe these are from the late 1970s. I am also including a pdf file containing these drawings.

For far more content, use a larger monitor and a full-width window.

Hundreds of cell phone users complained and asked me to for a simpler, mobile friendly site. In particular, they wanted me to limit each page to a small number of pictures and minimize my use of text. This new site provides what they asked for.