Bobbins were illustrated in the February 1968 N.S.S. News,

but it took a number of years before they were readily available

in the USA. Petzl introduced their first commercial bobbin in 1968 as well, and dominated the American

bobbin market for many years. Many cavers equate bobbins with the Petzl name,

but there are several other bobbin manufacturers and the buyer

should investigate several options before deciding which bobbin,

if any, to purchase.

Bobbins are constant friction rappel devices, with a friction

angle of about 480°. Some of the newer models have a rod which

can be used as a third bollard. This allows the rappeller to add

an incremental amount of friction during a rappel, but I have

never been too satisfied with the performance offered by this

approach. I consider the amount of friction provided by a bobbin

to be too small for many American cavers. The bobbin is a European

device, and in general most European cavers and climbers are lighter

than their larger Americans. I've had many discussions with people

claiming the bobbin’s friction is adequate. I've also noted that

most of those individuals have a body mass that is less than 70 kg (150 pounds).

Heavier cavers may want a device with more friction, as will cavers

hauling heavy loads down ropes. I find that the bobbins

low friction and lack of adjustable friction causes me to use

it only on drops of 15-20 meters or less, and only when traveling

light. On these drops the old type Petzl

Stop is perhaps the device I use most often, but on longer

drops I prefer to find a more suitable device.

There

are several ways to rig a double rope bobbin on a single rope

for extra friction during a rappel. Each of these methods involves

making extra turns around the bollards where the second rope would

normally run. When rigged in this manner double rope bobbins provide

substantially more friction than the normal "S" rigging.

Some of these methods have the highly undesirable side effect

of forcing the main rope to rub against itself, and cannot be

recommended. Another way to increase friction is to add a second

carabiner or maillon from the seat maillon to the tail end of

the rope as shown in the figure. On the other hand, a "C"

rigging can be used on either type of bobbin to reduce friction

if desired.

There

are several ways to rig a double rope bobbin on a single rope

for extra friction during a rappel. Each of these methods involves

making extra turns around the bollards where the second rope would

normally run. When rigged in this manner double rope bobbins provide

substantially more friction than the normal "S" rigging.

Some of these methods have the highly undesirable side effect

of forcing the main rope to rub against itself, and cannot be

recommended. Another way to increase friction is to add a second

carabiner or maillon from the seat maillon to the tail end of

the rope as shown in the figure. On the other hand, a "C"

rigging can be used on either type of bobbin to reduce friction

if desired.

The diameter (D) of the bollards is chosen as a compromise

between the desire for compactness and the need to provide a large

enough bending radius to prevent damaging the main rope. Most

bobbin bollards are about 30-35 mm. in diameter, or three

times the diameter of a standard 11 mm. caving rope. Since

the rope takes a 240° bend over each bollard, these may appear

to be rather sharp bends; however, tests performed by Tomaz Planina

(Obraba vrvi pri spuscanju z vrvnimi zavorami, Nase

jame, 17, 1976, pp. 15-22; Climbing ropes wearing out with

rope brakes, Nase jame, 19, 1977, pp. 15-22), indicate

that bobbins may damage the rope less than several other common

devices, including rappel racks and

figure eights. Although Mr. Planina’s

tests results are very informative, he rigged a few devices in nonstandard fashion during his tests, and so any conclusions should consider

the anomalous arrangements.

I find that most bobbins work best on flexible 9 mm. ropes,

although they tend to be faster on these thinner, more flexible

lines. The larger 11 mm. ropes can be used, but larger ropes

do not fit well in several of the bobbins. Furthermore, stiff

ropes such as PMI Pit Rope are more difficult to rig, although they are

still quite usable.

It is convenient to divide bobbin bollards into two categories.

The subdivision is somewhat arbitrary; essentially determined

by the inside diameter (d) of the rope groove. If this diameter

is larger than the rope diameter we have a U-groove; if it is

smaller the sides of the groove are formed into a V, yielding

a V-groove. The essential difference is that other factors being

equal, V-groove bollards have a higher effective coefficient of

friction due to ropes wedging between the walls of the groove.

As a result, a V-groove bollard increases the braking friction

of the bobbin. Now both bollards on a bobbin have essentially

the same friction angle. Since the friction (and hence heating)

is higher on the bottom bollard (with the higher rope tension),

most manufacturers attempt to even out the load by using a U-groove

for the lower bollard and a V-groove on the upper.

The bobbin has one unusual characteristic which may present

a hazard to the unwary. A number of cavers utilize the questionable

practice of providing "bottom belays," where a caver

positioned in the rockfall zone at the base of a drop stands ready

to apply tension to the rappel line if the rappeller seems to accelerate

out of control. This works for most devices where the braking

friction of a device is given by the well-known formula

where Fbrake is the braking force created by the device, Wcaver

and Wrope are the weights of the caver and the rope below the

device respectively, Tbelay is the tension supplied by the bottom

belayer until he gets killed by a falling rock, µ is the dynamic

coefficient of friction and θ is the friction angle of the

device. In most devices the bottom belay merely increases Tbelay,

thus slowing the caver, but with bobbins the increased tension

can result in the bobbin rotating, which reduces θ and hence

reduces the braking force. This could lead to the rappeler accelerating

even faster. Note that the additional tension might also arise

from the rappeler’s own braking effort (in this case the formula

is modified slightly). The over-rotation is limited if the rappeler

uses a second maillon to clip the rope below the descender to

the main seat maillon, as illustrated in the "increased friction"

figure above.

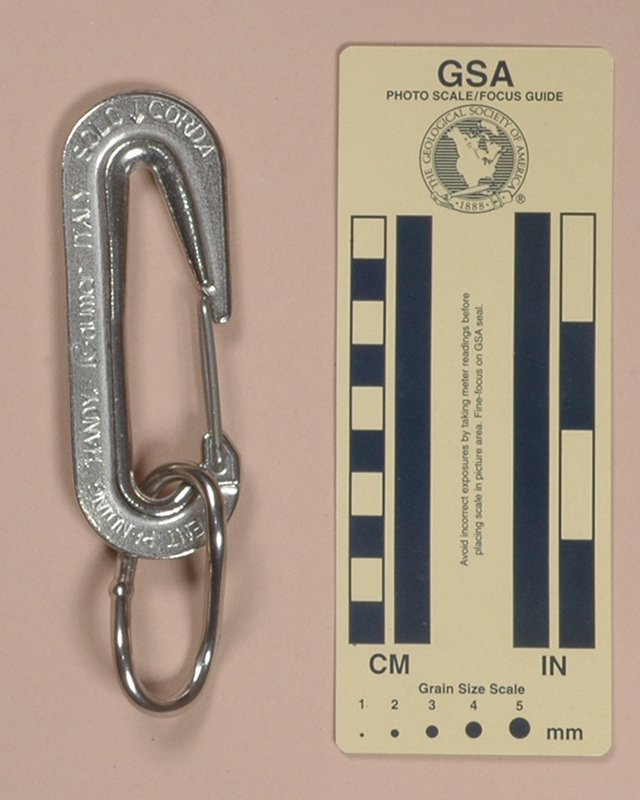

I prefer to attach bobbins to my seat harness so that the rope comes

out to one side, rather than away from or towards me. Since my

seat harness is designed for use with standard rappel racks, the

seat maillon sits in a "horizontal" position. This necessitates

the use of an additional maillon between the bobbin and the main

seat maillon in order to turn the bobbin 90°. The extra carabiner

also provides clearance for the mandatory safety carabiner connecting

the trailing end of the main line to the seat maillon (The

Raumer Handy

is a specialty carabiner specially designed for this purpose). The major

drawback to this arrangement is that it lengthens the hardware

chain. Other descenders, such as the Figure 8,

do not require all this extra hardware. When comparing

the bulk of the bobbin to other devices one should really penalize

the bobbin by the size and weight of a maillon and a carabiner.

I prefer to attach bobbins to my seat harness so that the rope comes

out to one side, rather than away from or towards me. Since my

seat harness is designed for use with standard rappel racks, the

seat maillon sits in a "horizontal" position. This necessitates

the use of an additional maillon between the bobbin and the main

seat maillon in order to turn the bobbin 90°. The extra carabiner

also provides clearance for the mandatory safety carabiner connecting

the trailing end of the main line to the seat maillon (The

Raumer Handy

is a specialty carabiner specially designed for this purpose). The major

drawback to this arrangement is that it lengthens the hardware

chain. Other descenders, such as the Figure 8,

do not require all this extra hardware. When comparing

the bulk of the bobbin to other devices one should really penalize

the bobbin by the size and weight of a maillon and a carabiner.

Petzl developed another credible alternative

to the second seat carabiner - the Freino.

The Freino

is essentially a double carabiner. The main (locking) carabiner

attaches the bobbin to the seat maillon while the trainling end

of the rope passes through the subsidiary (wire-gate) side. Although

the Freino

eliminates the need for one carabiner, the subsidiary side is

not large enough to pass the bights needed for locking a bobbin

off in the standard manner.

Petzl developed another credible alternative

to the second seat carabiner - the Freino.

The Freino

is essentially a double carabiner. The main (locking) carabiner

attaches the bobbin to the seat maillon while the trainling end

of the rope passes through the subsidiary (wire-gate) side. Although

the Freino

eliminates the need for one carabiner, the subsidiary side is

not large enough to pass the bights needed for locking a bobbin

off in the standard manner.

If a bobbin is not properly closed, it can open and let the

rope escape, resulting in an air rappel. I lost a long-time caving

friend when he allowed this to happen. Note that the

carabiner can press against the safety gate - this makes me nervous

as well. Since bobbins are popular among the rebelay crowd, there

are many opportunities to overlook whether the side plate is closed,

whether the safety is engaged, and whether the carabiner is resting

against then gate or not.

|

|

Warning:

Be

careful to ensure that the bobbin is closed with the safety catch

engaged before trusting your weight to the device. |

|

|

Under no circumstances should the autostop feature of so-equipped

bobbins be used to control one’s rate of descent! First, the amount

of control provided is generally insufficient. Second, to increase

friction one must release the control handle. This is contrary

to natural instinct, particularly if one starts accelerating out

of control. For this reason, one should never rely on the autostop

feature as a safety device. There is too much chance of responding

in the natural, instinctive manner rather than the proper one.

Finally, the autostop feature should not be relied on to hold

one stopped in mid-rappel, since it is too easy to bump the handle

causing an unintended descent (the Tracson

is the only device discussed here where the handle is not easily

bumped, in fact, it requires lifting one’s weight off the device

before the stop feature can be released). In fact, most of my

autostop bobbins slip under my own weight. Frankly, I'm not sure

what I can recommend the stop feature for, even though I've used a

Petzl Stop descender far more than

the non-stop models.

All my comments are oriented towards using these devices for

their design purpose. Unless I specify otherwise, this is limited

to a single person plus equipment descending ropes within the

9 to 11 mm. diameter range. My comments do not apply to descender

abuse, such as use in rescue lowering systems.

[ Top

| Return to Bobbins

| Return to Stop

Bobbins

| Return to Near Bobbins

]

There

are several ways to rig a double rope bobbin on a single rope

for extra friction during a rappel. Each of these methods involves

making extra turns around the bollards where the second rope would

normally run. When rigged in this manner double rope bobbins provide

substantially more friction than the normal "S" rigging.

Some of these methods have the highly undesirable side effect

of forcing the main rope to rub against itself, and cannot be

recommended. Another way to increase friction is to add a second

carabiner or maillon from the seat maillon to the tail end of

the rope as shown in the figure. On the other hand, a "C"

rigging can be used on either type of bobbin to reduce friction

if desired.

There

are several ways to rig a double rope bobbin on a single rope

for extra friction during a rappel. Each of these methods involves

making extra turns around the bollards where the second rope would

normally run. When rigged in this manner double rope bobbins provide

substantially more friction than the normal "S" rigging.

Some of these methods have the highly undesirable side effect

of forcing the main rope to rub against itself, and cannot be

recommended. Another way to increase friction is to add a second

carabiner or maillon from the seat maillon to the tail end of

the rope as shown in the figure. On the other hand, a "C"

rigging can be used on either type of bobbin to reduce friction

if desired.