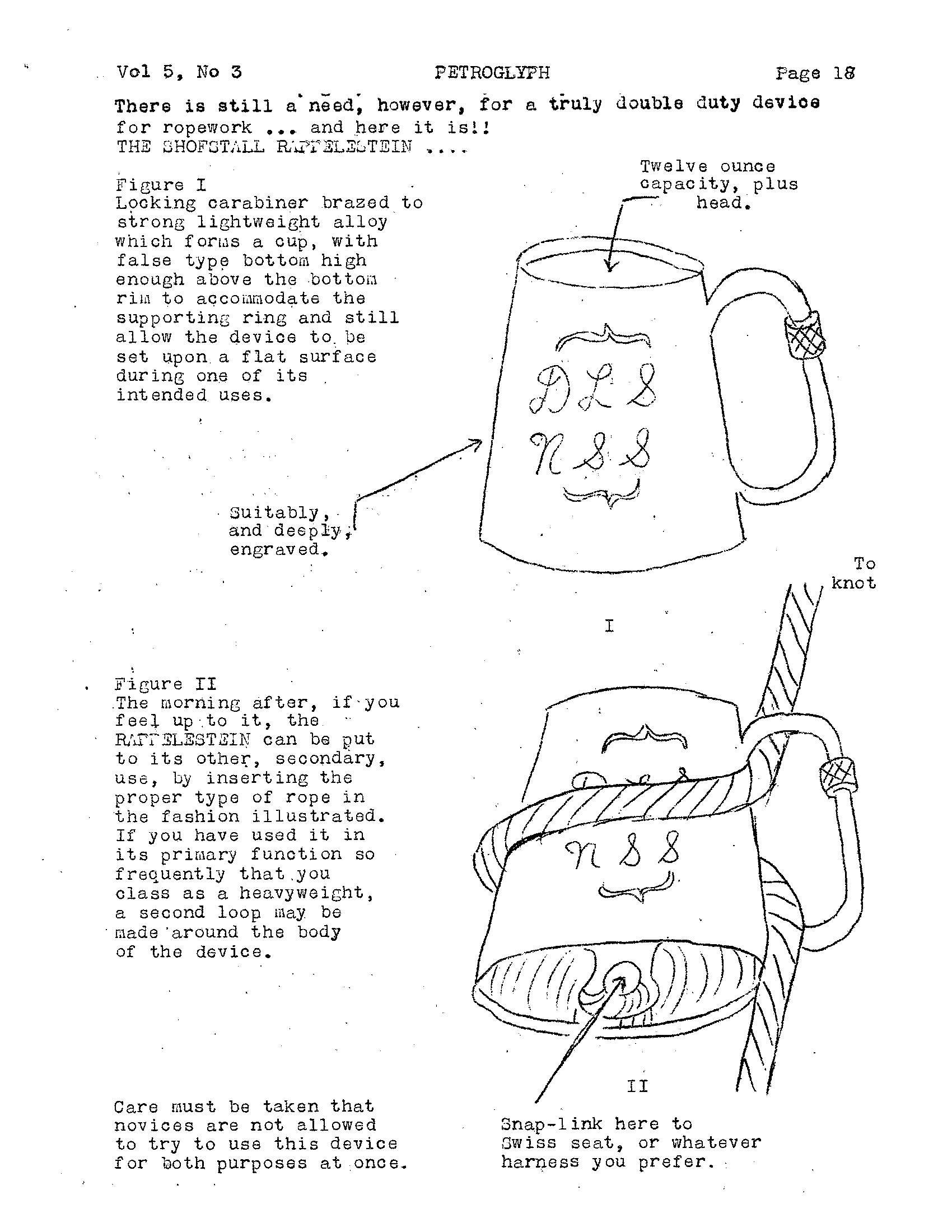

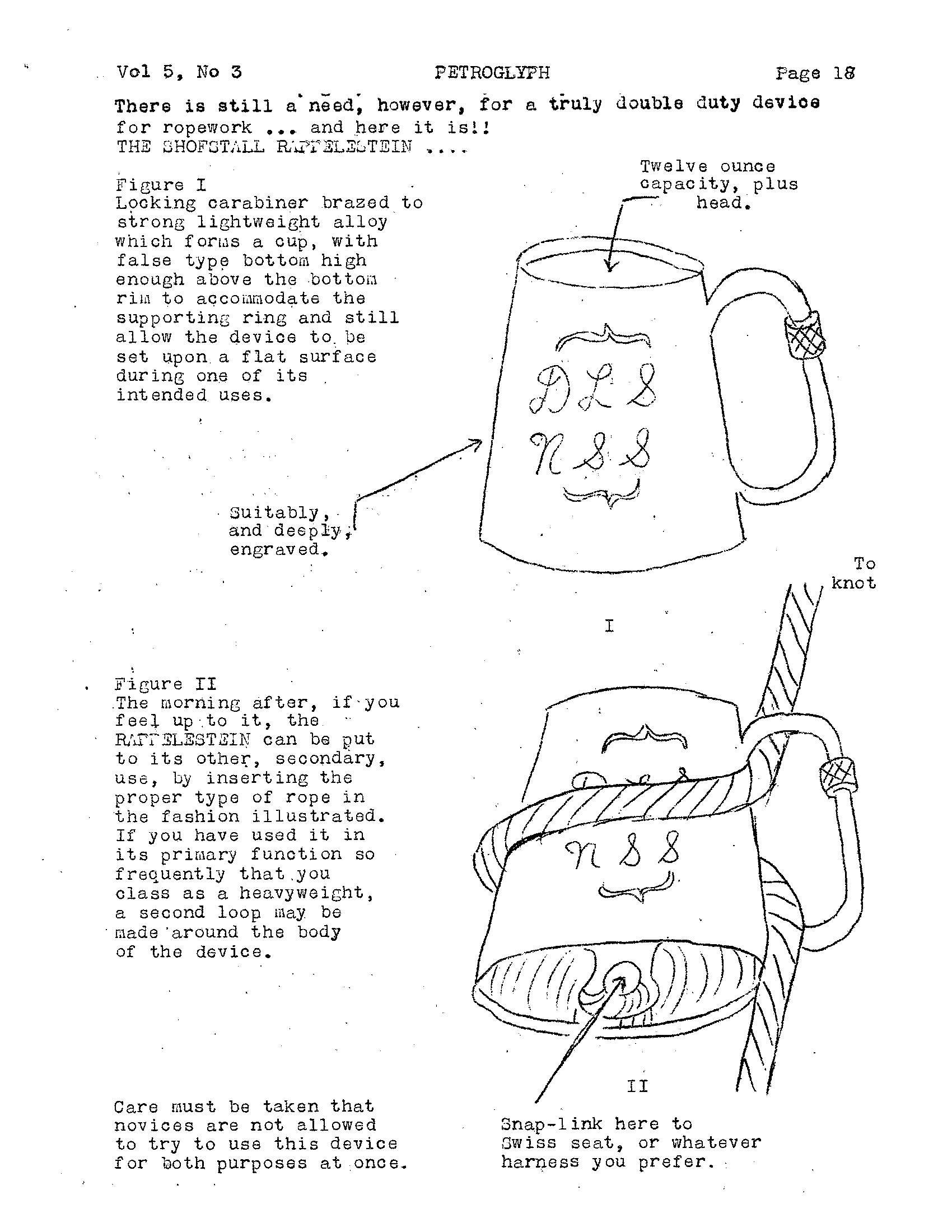

Technical Details

I acquired this Preaux Rappelestein from Brian Preaux in 2022.

My Preaux Rappelestein is 154 mm. tall, 174 mm. wide, 114 mm. thick, and weighs 964 g.

This rappelestein consists of 4" schedule 80 6061 aluminum pipe with an autolocking D carabiner

welded to the side, forming a handle. A 1/8" (3 mm) aluminum disc is welded inside an inch (25 mm.) from the bottom. A 1/2" (13 mm.) hole drilled below the carabiner provides an attachment point for a seat harness carabiner.

Brian engraved "Brian Preaux," ""PGH. GROTTO," and "N.S.S. 31513" on the outside of his Rappelestein.

Brian and I were members of the same caving club (Pittsburgh Grotto, N.S.S.) and we were on many caving trips together over the years. He liked my Rappelestein from the first, and around 1996 he made ten to share with other Grotto members. Seven of these are shown in the photo below. In 2022, Brian gave me his Rappelestein in exchange for me finishing two more from parts that he had left over from his original production run.

Rappelestein History

I. Don Shofstall invented the Rappelestein in 1965. The carabiner is welded to a slot in the side of the aluminum tube, and the bottom is an acrylic disc glued in place. I had a chance to buy Don's original at the NSS auction a few years ago, but the price was too steep for my wallet. I hoped that the purchaser would donate it to my collection, but they put it in the NSS museum instead.

|

|

|

Don's Original Rappelestein.

Now in the N.S.S. Museum in Huntsville, AL |

Don Demonstrates His Rappelestein.

Steve Shofstall, 2007. "Don Shofstall" [obituary].NSS News, v. 65, #12, p. 26 |

The original Rappelestein article.

Shofstall, Don, 1965. "Carbide Chatter." Petroglyph, v. 5, #3, pp. 17-18 |

II. Tom Rea saw Don's Rappelestein and had a close copy made for himself. Don may have made the copy, perhaps not long after he made his original. After Tom's passing, Laura Demarest found his Rappelestein in a tote of miscellaneous caving items that his family returned to the caving community. Laura nabbed this after it was tossed aside by others who seemed confused by it. Tom's model matched Don's but "upgraded" to a locking carabiner. We believe that Don made this one for Tom, but that is not confirmed. The similar dimensions and construction argue against independent origins. It seems that Tom never rappeled on his, but Laura did before trading it to me in 2023.

III. Once I heard about the Rappelestein, I had one made for myself, sometime around 1979. This was probably the third Rappelestein. Don's original was much taller and smaller in diameter. Not having seen Don's at the time, I chose to make mine closer to customary drinking mug dimensions. Mine has a welded aluminum bottom.

IV. Brian Preaux made ten Rappelesteins around 1996 and shared them with his friends. His Rappelesteins were popular among Pittsburgh area

cavers. No self-respecting member of our club would go to a party

without one. In 2022, Brian gave me one of his Rappelestein in exchange for me finishing two more from parts that he had left over from his original production run.

V. Amy Skowronski and I made a dozen Rappelesteins in 2021. I did the machining and Amy Skowronski TIG-welded the pieces together. The online caver response was openly hostile, because the Rappelesteins "were not made from hypoallergenic materials" and "drinking from aluminum can lead to Alzheimer's."

VI. Laura Demarest agreed to give me Tom Rea's Rappelestein in exchange for a new one, and so Amy Skowronski and I made a five more in 2023. Once again, I did the machining and Amy Skowronski TIG-welded the pieces together. Three of the five had oval carabiner handles and the other two used locking carabiners. This time we followed the original's dimensions. Instead of cutting a through slot for the carabiners, I milled a round-bottom groove that did not penetrate to the inside. This makes cleaning easier. I used a polycarbonate disc for the bottom, glued it in place, and then sealed it with epoxy resin layers.