Overview

[ Top

| Version A

| Version B

| Storrick – Shofstall

| Storrick – Rea

]

Rappelestein History

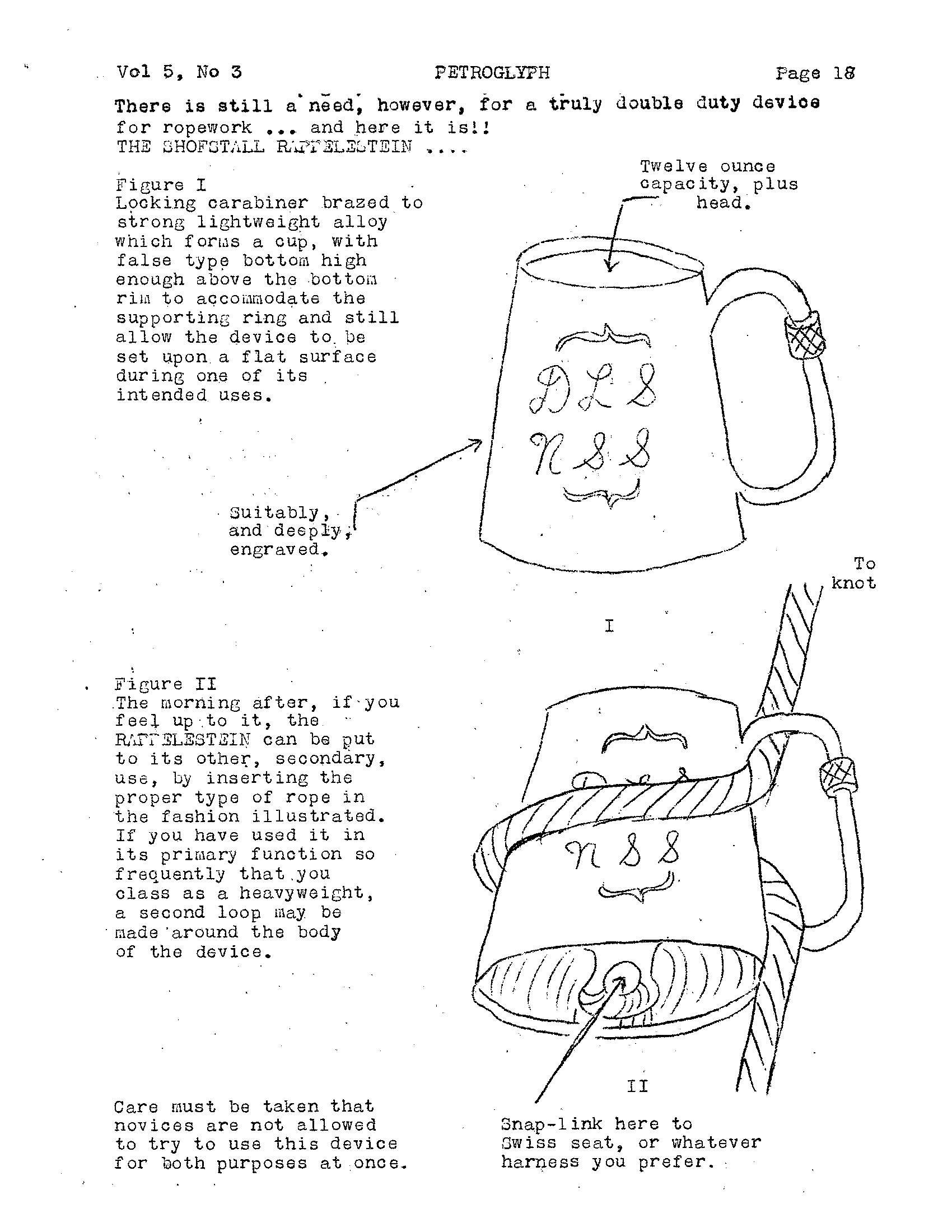

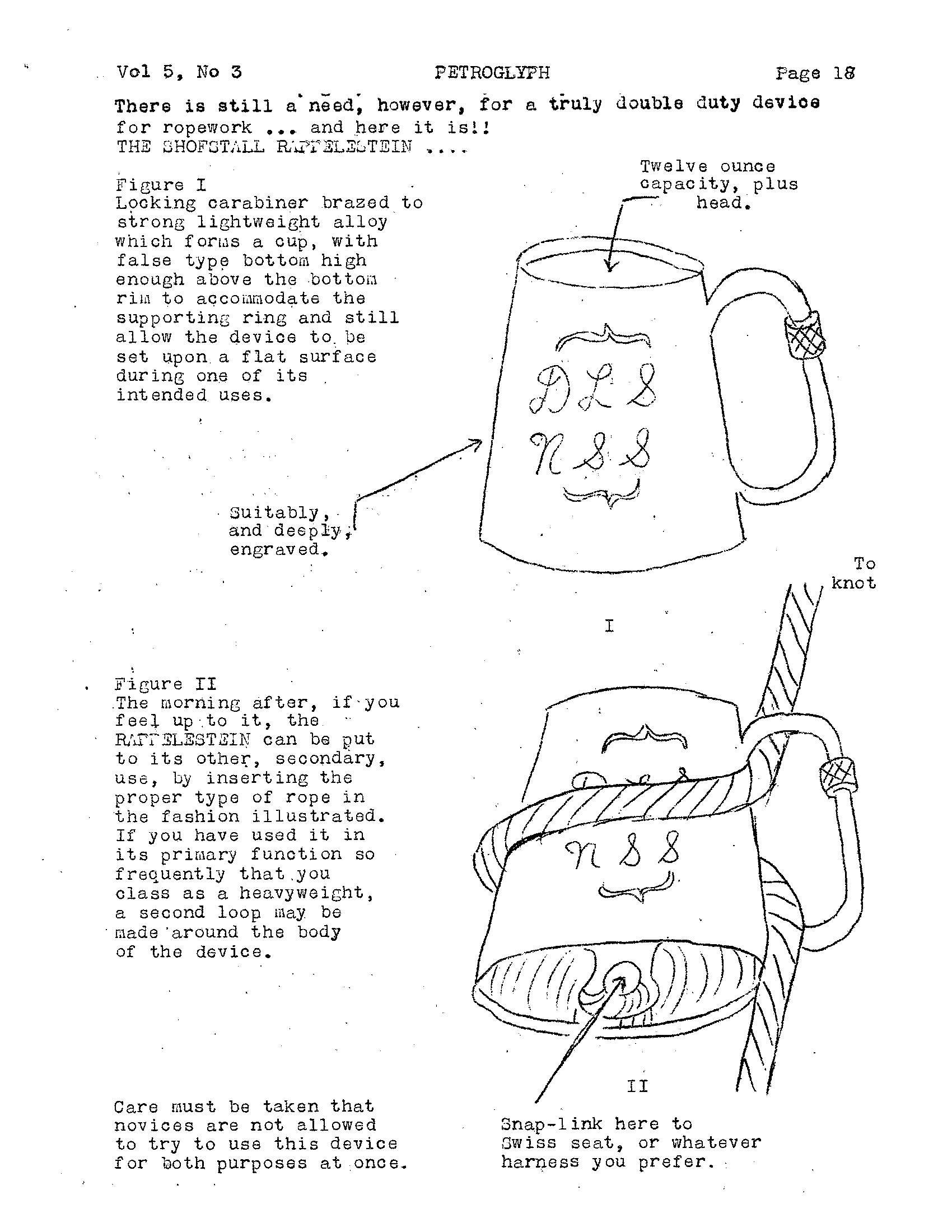

I. Don Shofstall invented the Rappelestein in 1965. The carabiner is welded to a slot in the side of the aluminum tube, and the bottom is an acrylic disc glued in place. I had a chance to buy Don's original at the NSS auction a few years ago, but the price was too steep for my wallet. I hoped that the purchaser would donate it to my collection, but they put it in the NSS museum instead.

|

|

|

Don's Original Rappelestein.

Now in the N.S.S. Museum in Huntsville, AL |

Don Demonstrates His Rappelestein.

Steve Shofstall, 2007. "Don Shofstall" [obituary].NSS News, v. 65, #12, p. 26 |

The original Rappelestein article.

Shofstall, Don, 1965. "Carbide Chatter." Petroglyph, v. 5, #3, pp. 17-18 |

II. Tom Rea saw Don's Rappelestein and had a close copy made for himself. Don may have made the copy, perhaps not long after he made his original. After Tom's passing, Laura Demarest found his Rappelestein in a tote of miscellaneous caving items that his family returned to the caving community. Laura nabbed this after it was tossed aside by others who seemed confused by it. Tom's model matched Don's but "upgraded" to a locking carabiner. We believe that Don made this one for Tom, but that is not confirmed. The similar dimensions and construction argue against independent origins. It seems that Tom never rappeled on his, but Laura did before trading it to me in 2023.

III. Once I heard about the Rappelestein, I had one made for myself, sometime around 1979. This was probably the third Rappelestein. Don's original was much taller and smaller in diameter. Not having seen Don's at the time, I chose to make mine closer to customary drinking mug dimensions. Mine has a welded aluminum bottom.

IV. Brian Preaux made ten Rappelesteins around 1996 and shared them with his friends. His Rappelesteins were popular among Pittsburgh area

cavers. No self-respecting member of our club would go to a party

without one. In 2022, Brian gave me one of his Rappelestein in exchange for me finishing two more from parts that he had left over from his original production run.

V. Amy Skowronski and I made a dozen Rappelesteins in 2021. I did the machining and Amy Skowronski TIG-welded the pieces together. The online caver response was openly hostile, because the Rappelesteins "were not made from hypoallergenic materials" and "drinking from aluminum can lead to Alzheimer's."

VI. Laura Demarest agreed to give me Tom Rea's Rappelestein in exchange for a new one, and so Amy Skowronski and I made a five more in 2023. Once again, I did the machining and Amy Skowronski TIG-welded the pieces together. Three of the five had oval carabiner handles and the other two used locking carabiners. This time we followed the original's dimensions. Instead of cutting a through slot for the carabiners, I milled a round-bottom groove that did not penetrate to the inside. This makes cleaning easier. I used a polycarbonate disc for the bottom, glued it in place, and then sealed it with epoxy resin layers.

[ Top

| History

| Version B

| Storrick – Shofstall

| Storrick – Rea

| Return to Vertical Spools

]

Version A

(#425)

Technical Details

My father had this Rappelestein made for me around 1979.

Version A is 150 mm. tall, 140 mm. wide, 89 mm. thick, and weighs 948 g.

This rappelestein consists of 3" schedule 80 6061 aluminum pipe with a Chouinard oval carabiner

welded upside down on the side, forming a handle. A 1/4" (6 mm) 6061 aluminum disc is welded inside an inch (25 mm.) from the bottom. A 1/2" (13 mm.) hole drilled below the carabiner provides an attachment point for a seat harness carabiner.

I stamped "Gary D. Storrick" and "NSS 12967" on one side, and "PERVERTICAL CAVER" and a "1" made of smaller 1s on the other side.

Don Shofstall invented the rappelestein in 1965 (Shofstall, Don, 1965. "Carbide Chatter." Petroglyph, v. 5, #3, pp. 17-18). Once I heard about it, I had this one made for me. Mine is

one of the earliest copies. Don’s original was much taller and

smaller in diameter. I chose to make mine closer to customary

drinking mug dimensions.

The rope is rigged

by passing one or two turns through the carabiner and around the spool.

My rappelestein does not give a very smooth rappel on stiff

ropes - as I feed the rope, the coils expand and I drop a few

inches, then stop, having to repeat the process.

My rappelestein gives the second worst rappel of any device in my

collection. As a stein, the aluminum is not ideal for slow drinkers, since

the beer gets warm quickly.

[ Top

| History

| Version A

| Storrick – Shofstall

| Storrick – Rea

| Return to Vertical Spools

]

Version B

(#3067)

Technical Details

We made a dozen rappelesteins in 2021. I did the machining and Amy Skowronski TIG-welded the pieces together.

Version B is 154 mm. tall, 148 mm. wide, 89 mm. thick, and weighs 738 g.

This rappelestein consists of 3" schedule 40 6061 aluminum pipe with a forged Black Diamond oval carabiner

welded on the side, forming a handle. A 3/16" (6 mm) 6061 aluminum disc is welded inside an inch (25 mm.) from the bottom. A 5/8" (16 mm.) hole drilled below the carabiner provides an attachment point for a seat harness carabiner.

I stamped my logo on the bottom.

Using schedule 40 instead of schedule 80 pipe made for a much lighter rappelestein than the previous version.

Amy welded the top side of the base as well as the bottom because she "didn't want beer getting in the crack and getting funky." She noticed "some weirdness going over the lettering," saying that it "welds weird." We suspect that the carabiner is 7075, an alloy known to present problems with welding. These rappelesteins should not be trusted for life support.

[ Top

| History

| Version A

| Version B

| Storrick – Rea

| Return to Vertical Spools

]

Storrick – Shofstall

(#3287)

Technical Details

We made three of these rappelesteins in 2023. I did the machining and Amy Skowronski TIG-welded the carabiner to the tube.

This rappelestein is 272 mm. tall, 123 mm. wide, 73 mm. thick, and weighs 902 g.

This rappelestein consists of 2-1/2" schedule 40 6061 aluminum pipe with an old REI oval carabiner

welded on the side, forming a handle. A 3/16" (6 mm) polycarbonate disc is glued inside about 1-3/4" (55 mm.) from the bottom. This is sealed top and bottom with a 4 mm. layer of clear epoxy resin. A 9/16" (14 mm.) hole drilled on one side provides an attachment point for a seat harness carabiner.

I based this one on Don Shofstall's original rappelestein, which is now in the N.S.S. Museum. I made the following changes:

- Don's original had a through slot for the carabiner, This made his harder to clean. For mine, I milled a round-bottom groove that did not penetrate to the inside. This makes cleaning easier.

- Instead of acrylic, I used a polycarbonate disc for the bottom, glued it in place, and then sealed it with a layer epoxy resin.

- I drilled a carabiner hole on only one side. This was an oversight that I could easily correct.

- I used an REI oval carabiner. I'm not sure which brand Don used.

[ Top

| History

| Version A

| Version B

| Storrick – Shofstall

| Return to Vertical Spools

]

Storrick – Rea

(#3288)

Technical Details

We made two of these rappelesteins in 2023. I did the machining and Amy Skowronski TIG-welded the carabiner to the tube.

This rappelestein is 272 mm. tall, 123 mm. wide, 73 mm. thick, and weighs 902 g.

This rappelestein consists of 2-1/2" schedule 40 6061 aluminum pipe with an old REI oval carabiner

welded on the side, forming a handle. A 3/16" (6 mm) polycarbonate disc is glued inside about 1-3/4" (55 mm.) from the bottom. This is sealed top and bottom with a 4 mm. layer of clear epoxy resin. A 9/16" (14 mm.) hole drilled on one side provides an attachment point for a seat harness carabiner.

I based this one on Tom Rea's original rappelestein, which Laura Demarest donated in exchange for one of these copies. Tom's was a copy of Don Shofstall's original, except Tom used a locking carabiner for the handle. Aside from this change, my Storrick – Rea rappelestein is identical to my Storrick – Shofstall rappelestein. As such, it differs from Tom's as follows:

- Tom's original had a through slot for the carabiner. This made his harder to clean. For mine, I milled a round-bottom groove that did not penetrate to the inside. This makes cleaning easier.

- Instead of acrylic, I used a polycarbonate disc for the bottom, glued it in place, and then sealed it with a layer epoxy resin.

- I drilled a carabiner hole on only one side. This was an oversight that I could easily correct.

- I used an Eiger locking carabiner. I'm not sure which brand Tom used (the markings are under the weld), but it looks like an Eiger.

- I flipped the carabiner upside-down at Laura's request.

[ Top

| History

| Version A

| Version B

| Storrick – Shofstall

| Storrick – Rea

]