Overview

[ Top

| Version B

| Version C

| Version D

| Return to Horizontal Spools

]

Version A

(#424)

Technical Details

I made my Storrick Rappel Hammer, Version A in 1991.

Version A is 250 mm. tall, 160 mm. wide, 110 mm. thick, and weighs 1957 g.

I built this Rappel Hammer out of galvanized pipe and

steel plate. The spool piece is 2-inch pipe, and the shaft is

1-inch. The shaft passes completely through the spool and is welded

at both top and bottom. The end caps were cut from 0.2-inch steel

plate. I soaked and rinsed the device in salt water several times

to give it an old, rusted look.

The Rappel Hammer design dates from the days of natural fiber

ropes. The Rappel Hammer is often rigged by looping the rope once

around the spool on one side of the shaft, and once or twice in

the same direction around the other, so that the rope path is

a helix. It is important to then pass the rope around the shaft

to help keep the rope on the spool piece.

An alternative rigging is to rig it like the rope path on

a Figure 8: bring the rope down

one side, pass it under the horizontal spool (90° bend), 180°

around the vertical shaft, and then back up and over the top (270°

around the spool). Once again, passing the rope this way around the shaft

helps keep the rope on the spool piece.

|

|

Warning:

There is no guarantee that the rope will stay on the Hammer. |

|

|

When I built this Rappel hammer, my intent was to mimic the

poor design and construction found on some very old, home made

devices. I even soaked it in salt water to add some rust and corrosion. Later, I made other versions and took more care in their construction.

Considering its size, weight, and crude construction, I can't imagine anyone making

and using a Rappel Hammer like this one.

[ Top

| Version A

| Version C

| Version D

| Return to Horizontal Spools

]

Version B

(#1071)

Technical Details

I made this Rappel Hammer in 2007.

Version B is 340 mm. tall, 82 mm. wide, 75 mm. thick, and weighs 2263 g.

I built this Rappel Hammer by tuning two pieces of 1018 carbon

steel. The spool is 3 inches (75 mm.) in diameter and

3-1/4 inches (82 mm.) long. The full diameter sections at

each end are each 3/8 inch (9.5 mm.) long. The central

section is 1-1/2 inches (37.5 mm.) in diameter and 1.6 inches

(40 mm.) long. The central section is drilled and tapped

for a 3/4"-UNC thread, and counter-bored to accept a short

unthreaded length of the shaft.

The shaft is 12 inches (300 mm.) long. The lower 3 inches

(75 mm.) are 1 -1/4 inches (37 mm.) in diameter,

while the remainder is 3/4 inch (19 mm.). The attachment

hole is 5/8 inches (16 mm.) in diameter, and the shaft

is thinned to 0.35 inch (9 mm.) in this area. I rounded the lower corners in 2021, something I planned to do from the start but did not get to for many years.

Version A was

(intentionally) a poorly constructed device that I assembled without

access to major metal working machinery. Once I acquired a

large

metal lathe, I decided to make a better Rappel Hammer. This

is the result.

I did not try to make a truly safe version (if

I had, I would have added rope guides); instead, I insisted that

this Rappel Hammer could effectively drive tent stakes. That is

why the end faces are flat and not hollowed to save weight.

The result is a very heavy rappel device that would make a more

effective effective speleo-medieval weapon than practical descender.

Considering its size, weight, and questionable safety, I can't imagine anyone making

and using a Rappel Hammer like this one.

|

|

Warning:

There is no guarantee that the rope will stay on the Hammer. |

|

|

[ Top

| Version A

| Version B

| Version D

| Return to Horizontal Spools

]

Version C

(#3089)

Technical Details

I made this Rappel Hammer in 2021.

Version C is 289 mm. tall, 138 mm. wide, 60 mm. thick, and weighs 1652 g.

This hammer is made from 7075 aluminum alloy. The head was made from 2-1/2" (64 mm.) round stock, and the shaft from 1-5/8" (41 mm.). The head is 138 mm. long and tapers to a 44 mm. diameter for the central 30 mm.

I attached the handle to the head by turning a 7/8-9 UNC thread on the handle. I drilled and through tapped the head accordingly, and counter-bored it about 6 mm. I hand-filed the shaft for a neat fit, and also hand-filed the top flush. Finally, I drilled a 10 mm deep hole from the top through the threads and installed an aluminum rivet, which I also filed smooth. This keeps the head from unthreading.

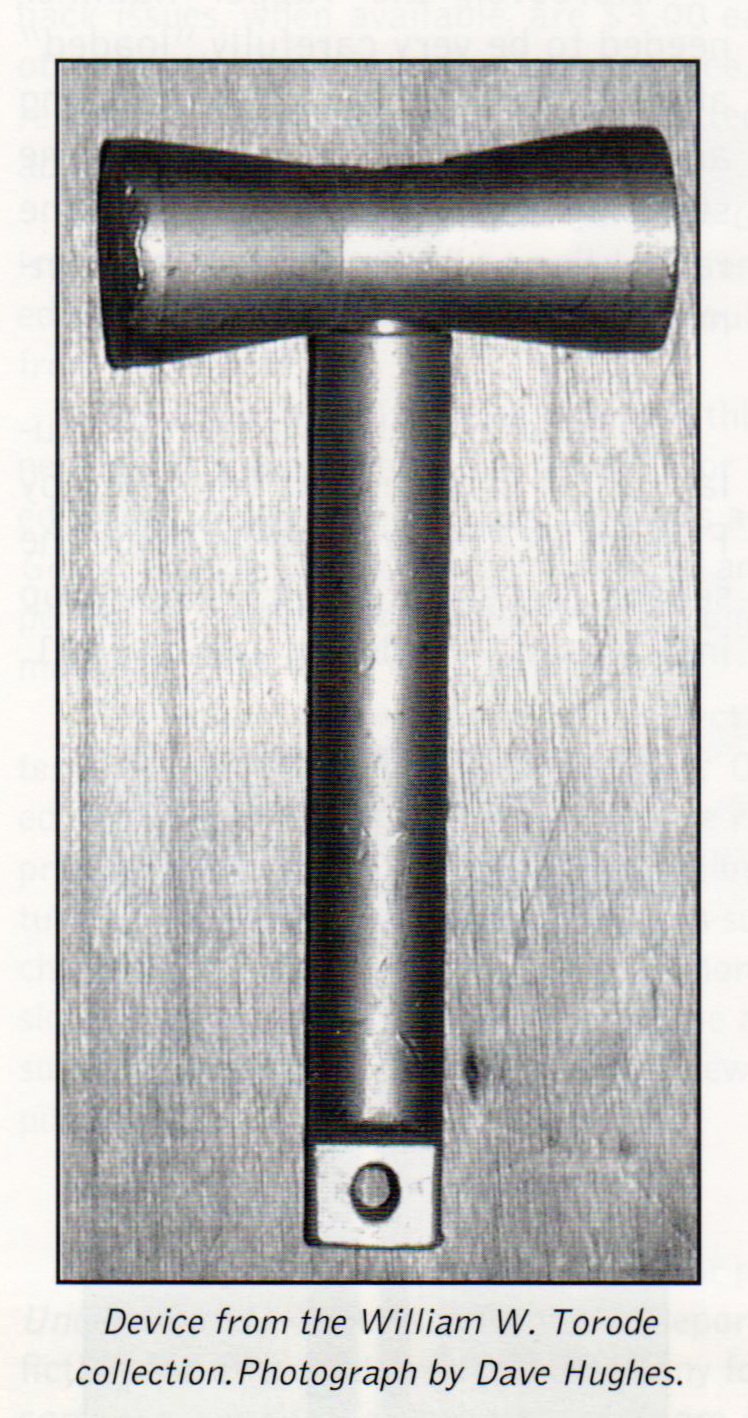

This time, I tried copied a hammer described in the July 2007 Georgia Underground (Dave Hughes & Bill Torode, "Photographic Portfolio of some Vertical Caving Relics." Georgia Underground, v. 42, #2, p. 2). I scaled my hammer’s dimensions from their photo, but used 1-5/8" stock for the shaft rather than 1-1/2" since that is what I had available. I also improved the fit between the shaft and head from the original. The original appears to be made from a softer aluminum alloy than mine, possibly 6061.

This hammer is still far to heavy for serious use.

|

|

Warning:

There is no guarantee that the rope will stay on the Hammer. |

|

|

[ Top

| Version A

| Version B

| Version C

| Return to Horizontal Spools

]

Version D

(#3090)

Technical Details

I made this Rappel Hammer in 2021.

Version D is 270 mm. tall, 87 mm. wide, 48 mm. thick, and weighs 597 g.

This hammer is made from 7075 aluminum alloy. The head was made from 2" (50 mm.) round stock, and the shaft from 1" (25 mm.). The head is 87 mm. long and tapers to a 25 mm. diameter for the central 10 mm.

I attached the handle to the head by turning a 5/8-13 UNC thread on the handle. I drilled and through tapped the head accordingly, and counter-bored it about 6 mm. I hand-filed the shaft for a neat fit, and also hand-filed the top flush. Finally, I drilled a 10 mm deep hole from the top through the threads and installed an aluminum rivet, which I also filed smooth. This keeps the head from unthreading.

This time, I tried copied a hammer described in the July 2007 Georgia Underground (Dave Hughes & Bill Torode, "Photographic Portfolio of some Vertical Caving Relics." Georgia Underground, v. 42, #2, p. 1). This was the hammer that Francis McKinney used for the 1961 second descent of 133 m. Surprise Pit in Fern Cave. The original appears to be made from a softer aluminum alloy than mine, possibly 6061. You can see extensive wear on the original.

I scaled my hammer’s dimensions from Dave’s photo in the article, but used 1-5/8" stock for the shaft rather than 1-1/2" since that is what I had on hand (it also fits my hands nicely). While we both used a threaded connection, the original was also welded while mine is not.

Unlike my previous hammers, this one is light enough for reasonable use; however, it is probably the least safe. The head extends only 31 mm. to each side of the shaft, and if the user allows any slack in the rope, especially when going over the edge, the rope is likely to come off the hammer. This is especially true if one is using classical 16 - 19 mm. manila rope.

|

|

Warning:

There is no guarantee that the rope will stay on the Hammer. |

|

|

[ Top

| Version A

| Version B

| Version C

| Version D

]