In 2006, I bought a PM-1640 for myself as a Christmas present. It has a 7.5 HP motor and a built-in cooling system and weighs 4200 lbs. I quickly learned that a spinning chuck and a coolant system were highly efficient means of throwing soluble cutting oil throughout the shop, so one of the first modifications that I made was to rig a splash guard. Later, I mounted a small shelf on the back of the splash guard to create a convenient place to store my quick-change tool holders. I run the lathe off of a 20HP rotary phase converter. This is not large enough for me to start the lathe in the two highest speeds (1300 and 2000 rpm), but I don't really need those speeds.

Proper tooling is essential for achieving the full value of any machine. The lathe came with a 10" 3-jaw chuck, a 12" 4-jaw chuck, and a 17" face plate. I later acquired an 8" 6-jaw chuck, 5C collet chuck, a 2J collet chuck, a driving face plate, and a fixture plate. I also made a back plate for a 6" 4-jaw chuck. I have a 5C collet closer that I intend to mount when I have a chance.

The lathe has plenty of power for my needs. I've been able to take cuts with a 0.2" depth of cut and 0.010" feed in 12L14 without strain, but this was only a test: I prefer to be more reasonable. Someone told me that "you can machine small items on a large lathe, but you cannot turn large items on a small lathe." This lathe is rugged enough to drill a 2" hole in cast iron, but it is rigid I was also able to drill a 1/16" hole in the end of a 1/8" rod. For one project, I had to do this 58 times in a row, and I did it without breaking a drill bit.

|

|

|

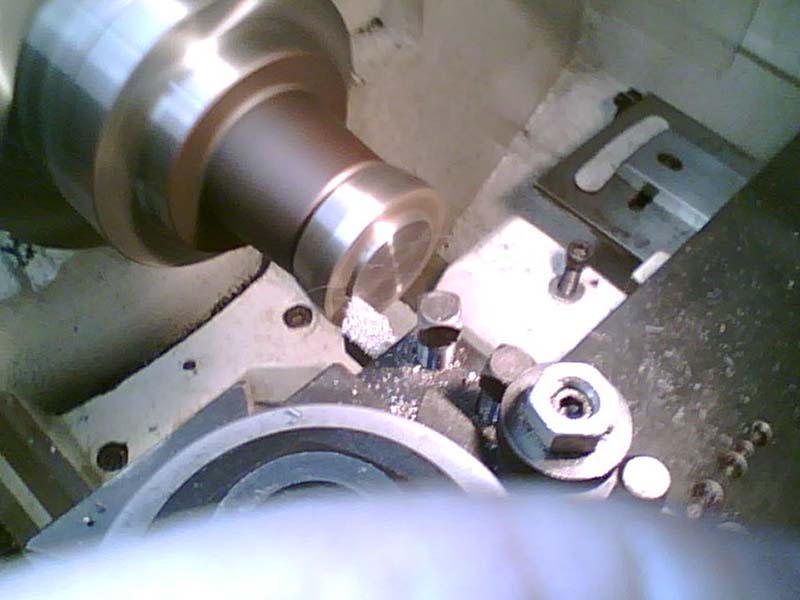

| Drilling a 1-13/16" hole in a cast iron disc | Drilling a 1/16" hole in a 1/8" brass rod |

Here are a few photos of some other projects:

|

|

|

| Facing a threaded back plate | Turning between centers on a mandrel |

|

|

| Turning a small part held in a step collet | Boring a cast iron disc |

| If you see a blank box below instead of a video, your browser may be stopping you from running scripts, and you should tell it to allow the blocked content: |

| Facing a Cast Iron Disc |

What I like

|

What I dislike

|

Problems (this was a new machine)

|

Other comments

|

‡In Destroy All Monsters, Manda wraps around a viaduct in much the same way that long, stringy chips wrap around my work piece when I don't have a proper chip breaker and proper feed for the work.

I wanted a small turret lathe to make some small parts for caving equipment, and in 2012 I purchased this lathe from Meridian Machinery in Kenosha, WI. I was living in Illinois at the time, so it was a short drive with a trailer to pick it up in person. They were very pleasant to deal with, and they threw in a number of 5C collets as well. During the test run, none of us noticed that the low/high speed lever was not working properly, but once I had the lathe back in my garage, I discovered the problem and was easily able to fix it. The only challenge was getting my large hands into a small space underneath the lathe to tighten a nut.

The picture above shows the lathe in my Michigan shop shortly after my move, so it is not tooled. Here are some pictures taken in Illinois where I had it tooled general purpose work:

|

|

|

| If you see a blank box below instead of a video, your browser may be stopping you from running scripts, and you should tell it to allow the blocked content: |

| Trimming Planer Stop Pins |

Here are some steps machining aluminum rollers for a caving descender. I start with an aluminum cylinder rough cut to length:

|

|

|

|

| 1. Stock positioning | 2. Close collet | 3. Face |

|

|

|

|

| 4. Center Drill | 5. Turn end clearance | 6. Continue, forming rope groove |

|

|

|

|

| 7. Finish turn the sides | 8. Drill for Axle | 9. Ream |

Once these steps were completed, I needed to reverse each roller to finish the other end, much like step #3.

What I like

|

What I dislike

|

Problems (this was a used machine)

|

Other comments

|

‡Hedora is a Smog Monster. When producing many parts and using a sulfur-based cutting oil, so is this lathe.

In 2004 I bought my Father's 10"x24" Wards (Logan) bench lathe. This lathe was larger than the Craftsman and had a few more features. Between this lathe and the G3617 milling machine that I purchased at about the same time, I started to develop a more serious interest in machining, and started learning the basic skills. This is the lathe that I used to make a series of dive lights out of turned aluminum. These feature knurled surfaces and a threaded bulb housing.

In 2004 I bought my Father's 10"x24" Wards (Logan) bench lathe. This lathe was larger than the Craftsman and had a few more features. Between this lathe and the G3617 milling machine that I purchased at about the same time, I started to develop a more serious interest in machining, and started learning the basic skills. This is the lathe that I used to make a series of dive lights out of turned aluminum. These feature knurled surfaces and a threaded bulb housing.

This lathe had a flat belt drive. The flat belt was adequate in theory, but in practice it was a nightmare. I never succeeded in getting the belt to work well. Although the lathe had a 2 HP motor, the belt would not transmit more than 0.2 HP before it would jump off the cone pulleys. I tried different belt materials, adjusted the alignment several times, and never solved the problem.

I loaned the lathe to a friend in 2006, but he eventually ran out of a need for it, and returned it in 2014.

What I like

|

What I dislike

|

Problems

|

Other comments

|

My Craftsman is a nice little 6" x 18" bench lathe. I bought it for small projects, but for many years I rarely had time to use it, and the limitations imposed by this lathe limited my motivation. I managed to adapt a tool post. vise to this lathe, and used it as a milling machine when I made perhaps my most useful items made on this lathe: custom safeties for my CMI UltrAscenders.

What I like

|

What I dislike

|

![]()