Technical Details

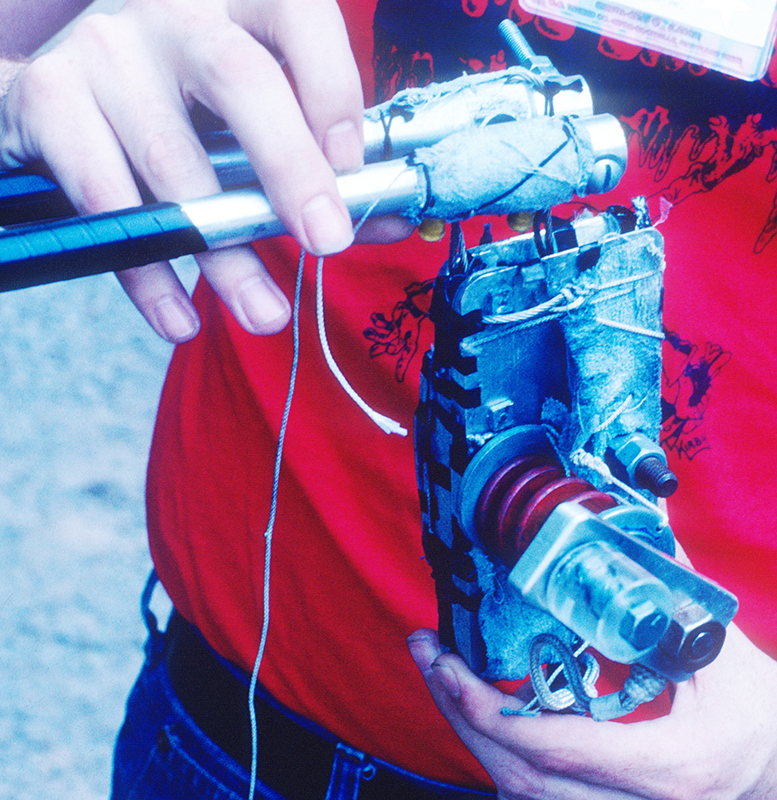

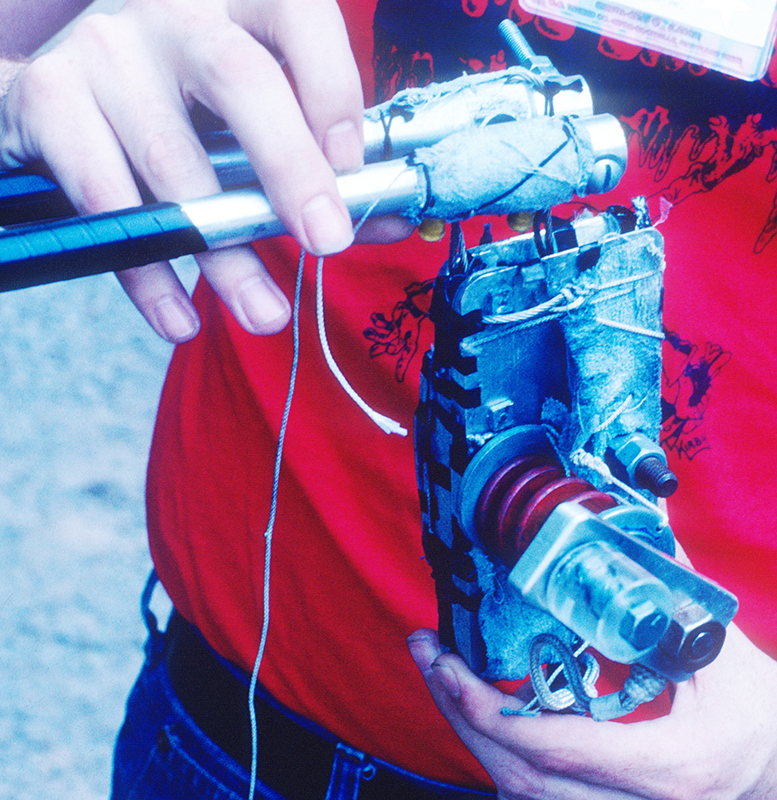

I made my Storrick – MacGregor Squeeze Brake in 2021.

This Squeeze Brake is 305 mm. tall, 155 mm. wide, 59 mm. thick, and weighs 1454 g.

The squeeze brake consists of two aluminum pressure plates with a crank handle for slow friction adjustments, and a "nutcracker" above for rapid control. The pressure plates are each 125 mm. tall, 76 mm. wide, and 9.3 mm. thick. Two pieces of 3.2 mm. thick aluminum strip are screwed to the inside of the plate to act as rope guides, with one guide on each side of the rope. The two plates are connected by a 3/8"-16 UNC bolt that acts as a hinge. A crank assembly consisting of a 78 mm. long, 25 mm. wide, 6.6 mm. aluminum strip, a 25 mm delrin knob, a 3/8"-16 UNC threaded rod, a 20 mm. OD, 25 mm. long medium load compression mould die spring, and various nuts, bolts, and washers. The threaded rod passes through holes in the pressure plates and enters a custom brass nut held on the outside of one plate by a milled aluminum housing.

The nutcracker consists of two 305 mm. long, 25 mm. aluminum rods turned down to 19 mm. for most of their length. A 1/4"-20 UNC stainless steel bolt passes through holes in the thick ends of the rods, forming a hinge.

The nutcracker rods are connected to the pressure plates with 3 mm. stainless steel cable. Stainless steel cable loops passing through holes at the base of each pressure plate provide a clip-in point.

|

|

Warning:

Do not build OR USE one of these. |

|

|

Most descenders generate the friction by bending the rope around the surface of the descender. The change in direction generates a normal force that generates friction that is nicely approximated by the well-known snubbing formula. But what if we want to eliminate the bend? There has been a lot of interest in that idea, leading to the development of squeeze brake descenders. A control systems theorist might immediately recognize that this would lead to instability, and that is exactly what the experimenters found out.

I'm not going to go into details of their history, but will refer the reader to Kirk MaGregor's 1986 article “Squeeze Brakes Up to 1982” in Nylon Highway #22. Kirk was one of several who tried a basic squeeze brake, and in his own words found, “Its speed fluctuated randomly over a wide range as it moved down the ropes, making accidents likely.” Others had similar experiences. Most people abandoned the squeeze brake idea after Sara Corrie's severe accident in 1978.

Kirk didn't give up, and eventually added a “nutcracker” above his brake. This gave him a means of rapidly controlling friction. He built a prototype, wrote that “No structural design was done on it, and some parts of it may not be strong enough to be safe,” and warned people not to copy his design. He used his squeeze brake on several occasions, including two July 1982 descents of Mount Thor (980 m.). One of these was a tandem rappel with Kathy Williams rappelling beneath him on the same rope. Kirk wrote, “During this rappelling, the tension in the rope below the brake varied from zero to 350 pounds…. I had no real problems controlling the brake's speed.”

The last time I talked to Kirk, he offered to donate his squeeze brake to my museum once he retrieved it from storage. Alas, he passed shortly afterward and the brake is now lost. At least I have a photograph of the brake, taken by Bob Thrun in 1982. Armed with Bob's photo and Kirk's article, I made my own brake, following Kirk's design rather than trying to improve it. Enhancements will come in a later version.

The last time I talked to Kirk, he offered to donate his squeeze brake to my museum once he retrieved it from storage. Alas, he passed shortly afterward and the brake is now lost. At least I have a photograph of the brake, taken by Bob Thrun in 1982. Armed with Bob's photo and Kirk's article, I made my own brake, following Kirk's design rather than trying to improve it. Enhancements will come in a later version.

Like Kirk's, mine is very much a prototype, and I warn people not to copy it. I think it is unsafe – in fact it is downright scary – and there are quite a few things I would change before trusting it. I have not had a chance to test the brake properly. The longest available drop near me is a measly 290 meters, not enough to overheat my MegaRack bars and preposterously short for a squeeze brake capable of many times that length. All I can do is try it on small drops.

Playing with my brake, I found that rigging it was more difficult than expected. I can see why Kirk went to a single hinge bolt after initially using four, as this makes inserting the rope easier. The nutcracker needs to be skewed to admit the rope. Inserting the tension screw while holding all the parts in alignment would be easier with a couple extra hands. The brake can be attached to a fully tensioned line, something that is more difficult with a rack or bobbin. As Kirk noted, the rope tends to come out of the brake when passing over a sharp lip, something a better deign could easily address.

Obviously standing in the drop zone under the rappeller with the idea of providing a bottom belay won't work with a squeeze brake. Without snubbing, adding tension below the brake does not provide more friction and does not slow the rappeller - in fact, it tends to do the opposite. Similarly, using one’s braking hand does not better below a squeeze brake than it would above the brake.

Kirk’s article ended with the prophetic "Perhaps the Thor Brake will be the last of the squeezers." While there have been commercial hybrids that partially use the squeeze-brake, I know of no fully successful, safe squeeze brakes.

|

|

Warning:

Do not build OR USE one of these. |

|

|