Overview

[ Top

| P/N 071-1

| Return to Poly-Bollards

]

Mark 2 (#1004)

Technical Details

I acquired my Fallright Controlled Rate Descender, Mark 2 from Steven Ward on eBay

in January 2006.

My Fallright Controlled Rate Descender, Mark 2 is 132 mm. tall, 123 mm. wide, 34 mm. thick, and weighs 349 g.

The Controlled Rate Descender consists of three bollards, mounted

between two side plates that pivot on a fourth attachment post.

An adjustment screw assembly helps vary the friction in the device.

Each side plate is a roughly pentagonal piece of black anodized

1/8-in (3.3 mm.) aluminum. The plates are 132 mm. high with a curved

top. The top half of each plate is 60 mm. wide for the top 66 mm.,

then taper to join a 22 mm. diameter circular arc at the bottom.

The side plates are attached to a 16 mm. diameter steel attachment

post at the center of the bottom circular arc by round-head hex-socket

cap screws and washers. The front plate is tightly bolted to the

post, while the rear plate is loosely bolted. A spring acts to

close the rear plate.

The top and bottom rope bollards are bolted

to the front plate with two small 3.5(?) mm. round-head hex-socket

cap screws to prevent rotation. The center bollard is similarly

bolted to the rear plate. The bollards are made of unfinished aluminum. Each rope bollard

has a groove that fits into a corresponding notch in the opposite

plate. The bollards are 16 mm. wide, measured from between the

insides of the side plates. The top three bollard diameters are

26.5 mm. in the center, widening to 28 mm. about 1 mm. from the side

plate, then constant. The three bollards are mounted 106.5 mm.,

65 mm. and 44.5 mm. from the center of the pivot point. When the

rope is inserted, this asymmetrical arrangement ensures that the

rope is pinched between the center and bottom bollards only.

The rear plate has a small aluminum block bolted to the upper

left inside of the plate. A 10 mm. threaded rod (with about 6 right-hand

threads per centimeter) passes through this plate and presses

against the upper bollard. A plastic wing-nut attaches to the

outside of the rod. The sides of the cross piece have red and

green painted dots on them.

The front piece is stamped "P\LOADED," "B\ No

20." and "SWL 2 MEN." A sticker on the front plate

has "CRD" and a rigging illustration. A sticker on the

rear plate has "A411."

According to Dave Allport, Fallright licensed the Troll

Allp design for their Controlled Rate Descender. The Controlled

Rate Descender uses a right-hand threaded rod while the one on

the Troll Allp has a left-hand

thread. Most right-handed users seem to prefer the left-hand thread

on the Troll Allp since turning

the wing nut away (clockwise) adds braking. Although I am right-handed,

I usually I rappel left-handed (unless cave conditions favor right-handed

rappelling), so I prefer the right-hand thread on the Controlled

Rate Descender. Actually, getting used to either arrangement is

a minor matter, but randomly switching between the two can create

momentary confusion, particularly in the dark.

By analogy with the Troll Allp,

the Controlled Rate Descender appears to

be designed for 7/16 in. (11 mm.) to 1/2 in. (13 mm.) rope. It performs

much like the Troll Allp as

well. Part of the friction is obtained by squeezing the rope between

the center and bottom bollard. As one turns the rod clockwise,

it forces the rear plate in the direction that separates the center

and lower bollard, reducing the rope squeezing action. The friction

decreases accordingly. This process only continues until there

is no more squeezing. After that, there is very little change

in friction. This is rather obvious, because there is no large

change in the snubbing angle once the bollards are separated.

The practical effect is that if one starts a rappel with the rod

screwed in and finds out that the friction is insufficient, it

will take many turns before the friction is significantly increased.

One should always start with the rod unscrewed as far as practicable

for the conditions.

|

|

[ Top

| Mark 2

| Return to Poly-Bollards

]

P/N 071-1 (#2467)

Technical Details

I acquired my Fallright Controlled Rate Descender, P/N 071-1 from Doug Schmitt in 2017.

My Fallright Controlled Rate Descender, P/N 071-1 is 147 mm. tall, 125 mm. wide, 38 mm. thick, and weighs 590 g.

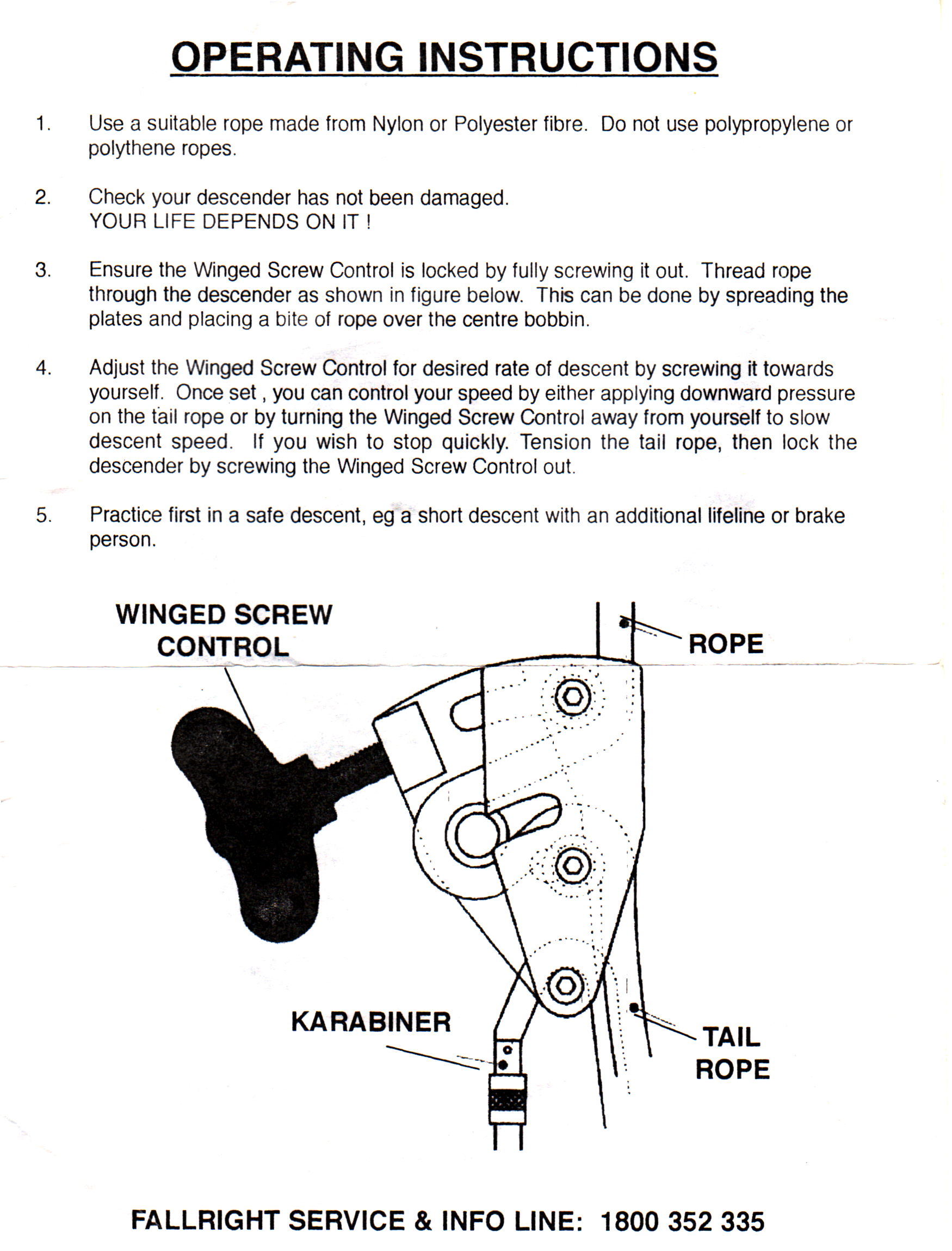

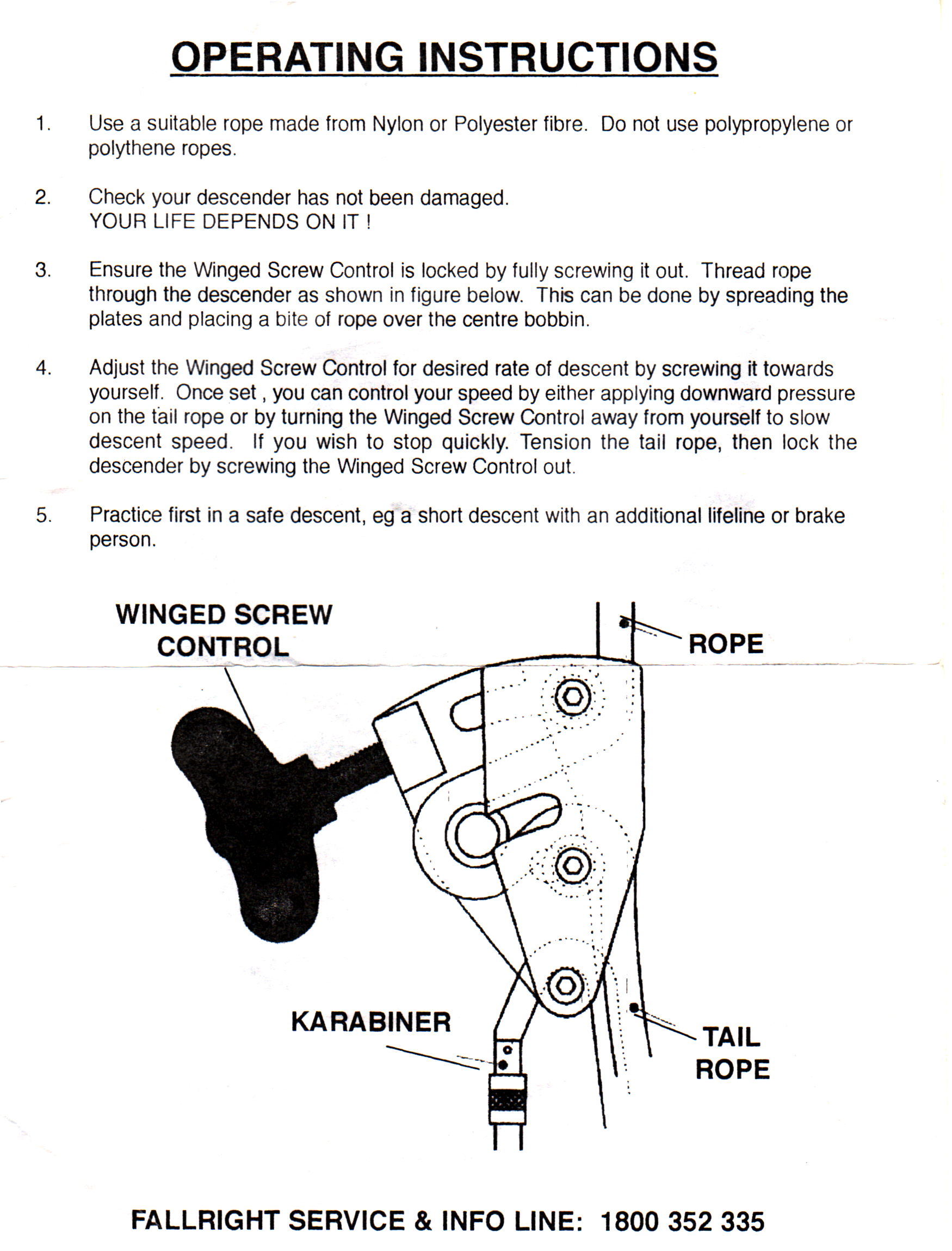

The Controlled Rate Descender consists of three bollards, mounted

between two side plates that pivot on a fourth attachment post.

An adjustment screw assembly helps vary the friction in the device.

Each side plate is a roughly pentagonal piece of green anodized

3.8 mm. aluminum. The plates are 147 mm. high with a curved

top. The top half of each plate is 54 mm. wide, widening downward to 69 mm for the top 65 mm., then taper to join a 25 mm. diameter circular arc at the bottom.

The side plates are attached to an 18.5 mm. diameter steel attachment

post at the center of the bottom circular arc by round-head hex-socket

cap screws and washers. The front plate is tightly bolted to the

post, while the rear plate is loosely bolted. A spring acts to

close the rear plate. A latch assembly near the bottom of the front plate houses a spring-loaded pin that engages a shallow arcuate slot milled in the rear plate. When extended, this pin prevents opening the device. A lever on the pin engages a sloped cut on the housing so that turning the pin 180°retracts the pin into the housing and out of the slot, allowing the plates to open.

The top and bottom rope bollards are bolted

to the front plate with two small 3.5(?) mm. round-head hex-socket

cap screws to prevent rotation. The center bollard is similarly

bolted to the rear plate. The bollards are made of unfinished aluminum. Each rope bollard

has a groove that fits into a corresponding notch in the opposite

plate. The bollards are 15 mm. wide, measured from between the

insides of the side plates. The top three bollard diameters are 27.8 mm. in the center, widening to 31 mm. about 1 mm. from the side

plate, then constant. The grooves in these bollards are triangular, not circular. The three bollards are mounted 116 mm.,

75 mm. and 47 mm. from the center of the pivot point. When the

rope is inserted, this asymmetrical arrangement ensures that the

rope is pinched between the center and bottom bollards only.

The rear plate has a small aluminum block bolted to the upper

left inside of the plate. A 10 mm. threaded rod (with 10 right-hand

threads per centimeter) passes through this plate and presses

against the upper bollard. A plastic wing-nut attaches to the

outside of the rod. The sides of the cross piece have red and

green painted dots on them.

The front piece is printed with "UNLOCK" and "LOCK" near the latch mechanism, "FALLRIGHT," "CRD" and a rigging illustration, "SWL 2 MEN," "MB: 20.50kN," "S/N" with "271" followed by a hand-engraved "271," "B/N 01/99," "PN: 071-1."

This version of the Controlled Rate Descender (CRD) is much heavier than the Mark 2. It weighs about twice what others (the original Troll Allp or the USA version) in that class weigh. Although I have a certain fondness for the Allp design, this one is too heavy for a "plain" Allp - I would rather use the Troll Pro Allp Tech, which weighs about the same as this CRD.

The locking pin on the 071-1 is a nice design and it works well.

The grooves in the bollards are shallow V-shaped grooves, not semicircular grooves. This simplifies manufacturing, and for such shallow grooves, the V shape has absolutely no effect on performance.

My operational comments on the Mark 2 apply to this CRD as well.

[ Top

| Mark 2

| P/N 071-1

]