Overview

History

Boris Rogelja founded Single Rope Technique Equipment (SRTE) in 1980. Capital Safety Group acquired SRTE in 2011 and their devices started showing DBI-SALA, Capital Safety, and/or Rollgliss™ markings. Some of these continued to show SRTE markings, and some did not. There does not appear to be a specific date when the markings disappeared. Different devices removed the SRTE logo at different times. 3M acquired the Capital Safety Group in 2015 and the Single Rope Technique Equipment markings disappeared completely. Since the device designs and construction retained continuity while the branding changed, I see no reason to put the different brands on separate pages.

[ Top

| SRTE v. B

| DB i-SALA 2Way v. A

| DB i-SALA 2Way v. B

| DB i-SALA Double v. A

| DB i-SALA Double v. B

| Return to PolyBollards

]

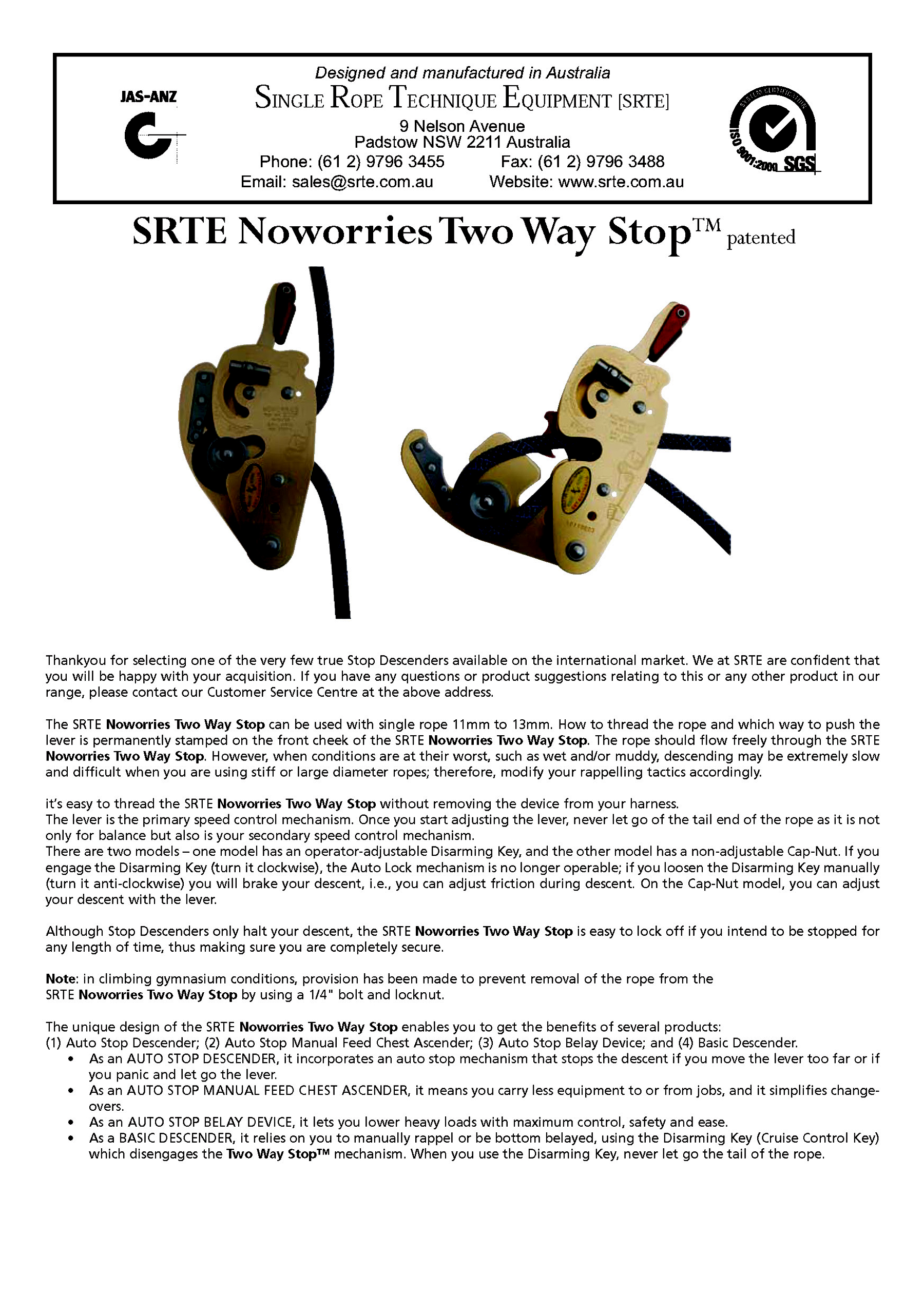

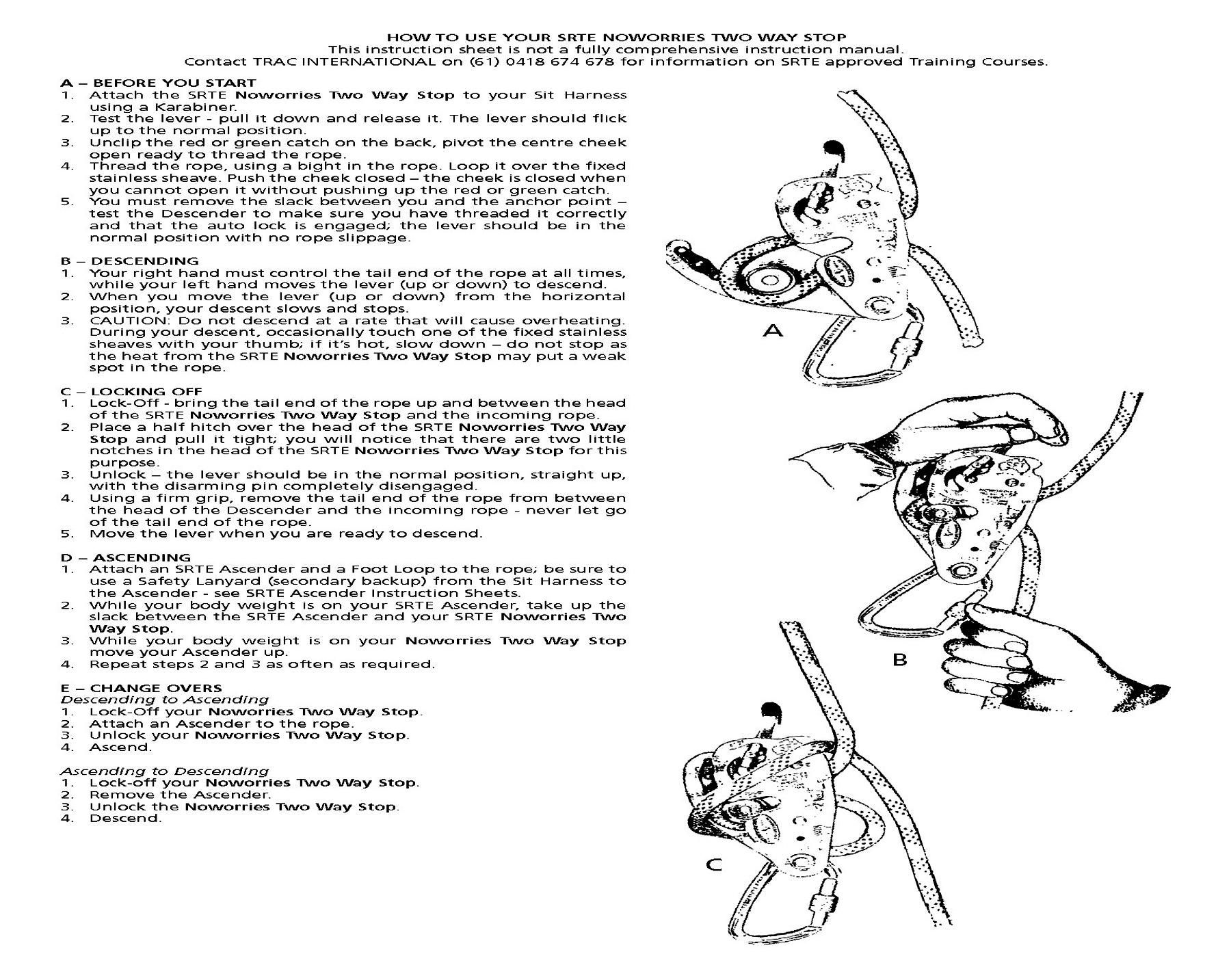

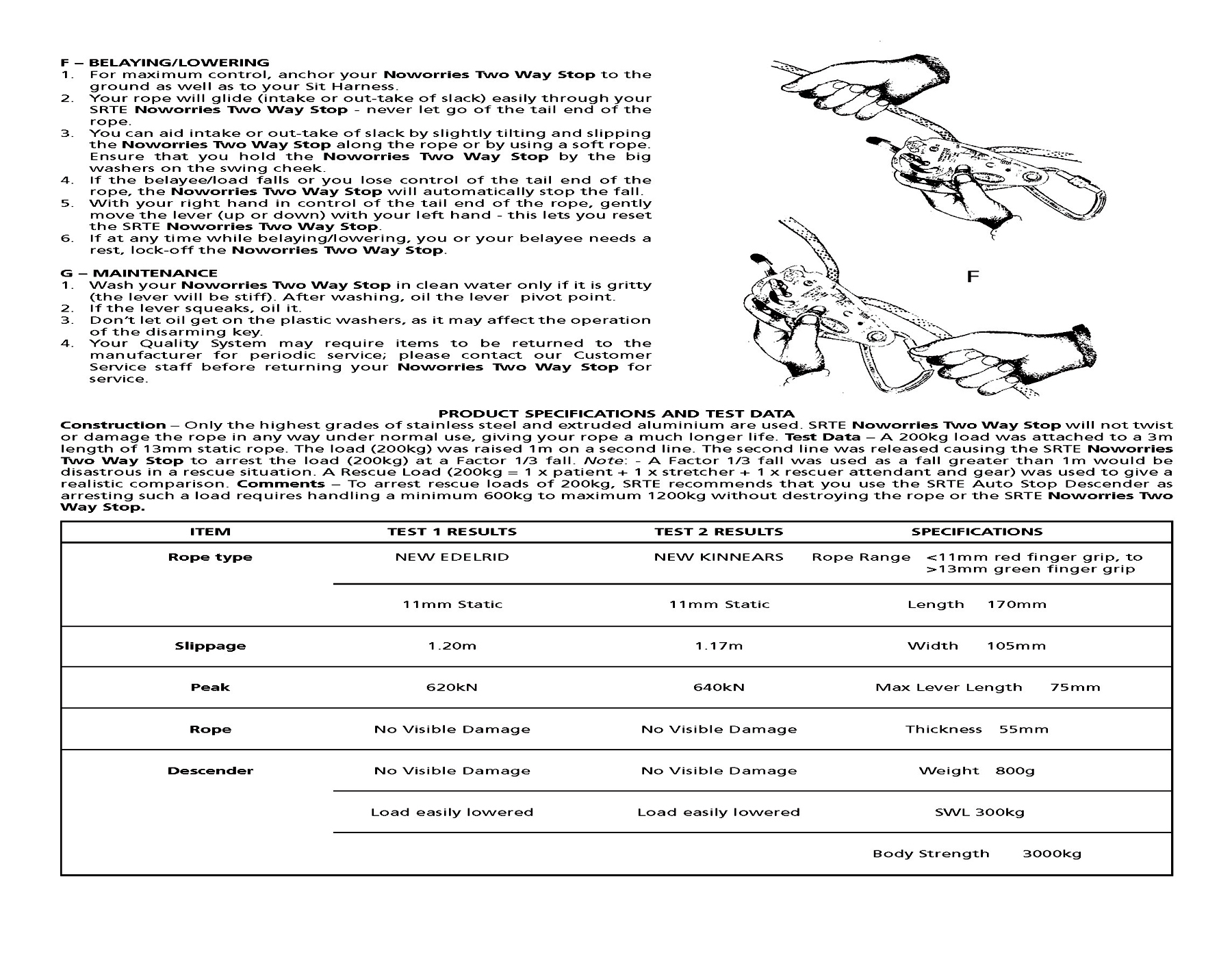

SRTE Two Way Stop

Version A

(#555)

Technical Details

I acquired my Two Way Stop from Single Rope Technique Equipment in October

1999.

The Two Way Stop uses many of the same pieces as the Belay

Stop. I've used gray text for the parts of the description

that apply to both devices.

The Two Way Stop consists of three bollards.

The top and bottom bollard are mounted between two fixed plates,

while the third is mounted on swinging plate. The pivot that serves

as an attachment post. A lever mounted between the fixed

plates controls the position of the swinging plate, and hence

the friction.

Each fixed plate is an irregular piece

of gold anodized 4 mm. aluminum. The plates are 167 mm.

high with curved top and sides. The top half of each plate is

about 67 mm. wide at the top, increases to 79 mm. about

50 mm. down, then the plates taper to join a 17 mm.

diameter circular arc at the bottom. Both plates have a shallow

notch at the top right (facing the front of the device) to help

hold the rope while tying off. The rear plate has two smaller

plates attached to house a spring-loaded catch. The fixed plates

are attached to a 13 mm. diameter steel attachment post at

the center of the bottom circular arc. The fixed plates are rigidly

riveted to the post. The top and bottom rope bollards are also

riveted between the fixed plates. A lever made of three

layers of 4 mm. aluminum pivots on a rod at the level of

the top bollard. This lever moves the swinging plate as described

later. A threaded rod on the lever fits into a semicircular arc

cut from the front plate. A disarming key on this rod can be tightened

to hold the lever in any desired position. A green aluminum stamping

folds out from the end of the lever to extend its length.

An irregular swinging plate is hinged

to the attachment post. The middle bollard is mounted on this

plate. The rivet is extended on the rear side of the swinging

plate so that the spring-loaded catch can engage and keep the

device closed. The end of the catch spring tends to open the swinging

plate. Each end of this rivet has a washer that extends over the

sides of the corresponding notches in the fixed plates.

A steel plate is riveted to the swinging plate. A roller on the

control lever presses against this plate. When the lever is up,

the swinging gate can close. Pulling the lever down cams the swinging

plate open, decreasing the friction provided by the bollards.

This continues until the lever is in the intermediate position.

Pulling it past the nose in the steel plate allows the rope tension to pull the swinging plate closed. The shape of the plate also pushes the lever further down. The net result is a substantial increase in

friction.

The bollards are made of stainless steel.

The bollards are riveted to the appropriate plate and pinned so

they cannot rotate. Each rope bollard has a groove that fits

into a corresponding notch in the appropriate plate (i.e., the

fixed bollards have a notch to clear the swinging plate and vice

versa). The bollards are 16 mm. wide, excluding the notch.

The top and bottom bollards appear to be identical. The bollard diameter

is 28 mm. in the center, and widens to 32 mm. about

1 mm. from the edge, then remains constant. The bollard on the swinging plate is smaller, with a 26 mm. center diameter. The three bollards

are mounted 112 mm., 72 mm. and 47 mm. from the

center of the pivot point. When the rope is inserted, this asymmetrical

arrangement ensures that the rope is pinched between the center

and bottom bollards only.

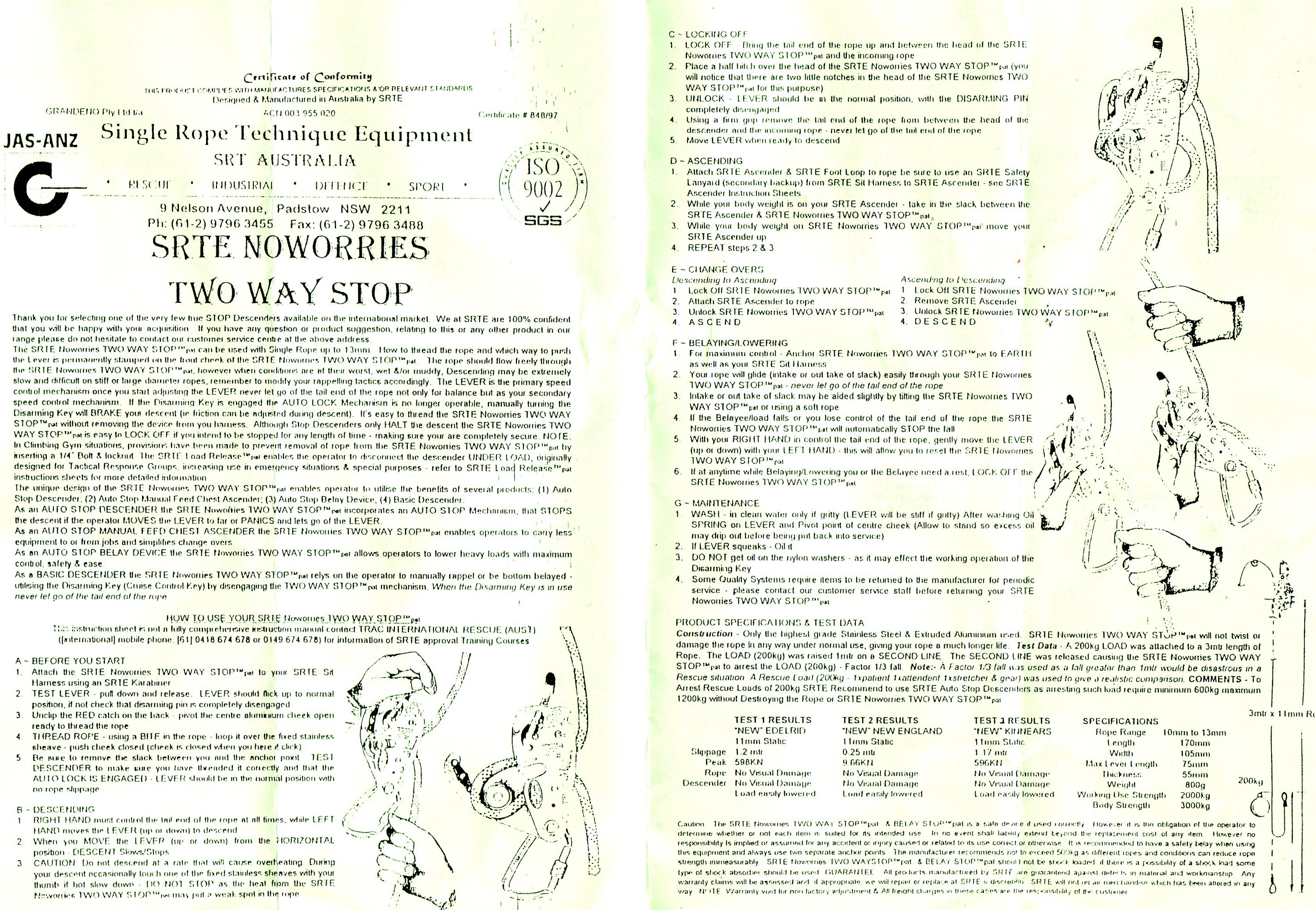

The front piece is covered with stampings,

including

- The Single Rope Technique Equipment logo (SRT

inside an outline of Australia)

- A double arrow with "GO"

and "STOP to indicate which way to turn the adjustment screw

- NOWORRIES

TWO WAY STOP

PATENTED

S.W.L. 300KG

MAX 2000KG

- An illustration showing how to rig

the device and the word "UP"

- A serial number (19921501)

The safety catch has an arrow and the

word "OPEN" to assist the intellectually challenged.

Like all Single Rope Technique Equipment, the Two Way Stop

is well made, rugged, strong, and a bit heavy.

Like all Single Rope Technique Equipment, the Two Way Stop

is well made, rugged, strong, and a bit heavy.

The green lever extension indicates that my Two Way Stop was

designed for ropes greater than 12 mm. in diameter. I did not thoroughly test the Two Way Stop, so I can't say how

it performs with different ropes and under various conditions

of mud and water. What I have tested is its performance on clean,

dry 11 mm. PMI pit rope, a rather stiff caving rope, on short

drops. In these limited tests it has performed very well, despite

the fact that I was using a rope that the manufacturer said the

device was not suited for. Your mileage may vary, so don't do

this. The stop function worked in both directions.

The Two-way stop is designed for the traditional right-handed

user who brakes with their right hand at the right hip. Although

I'm right-handed, I prefer to brake left-handed, so I’d rather

have a mirror-image version, although this hardly is significant

enough to be worth worrying about.

The Two Way Stop addresses the

problem of the brain-dead not releasing the stop handle while

flying out of control, because pulling and pushing will both stop

the Darwin Candidate. The corporate lawyers will love this but

for trained users, this feature is less important. Note that Single

Rope Technique has provided a disarming key to hold the lever

in a desired position. Skilled users will appreciate this, Darwin

Candidates will use it to improve the gene pool.

I believe that the Two Way Stop can do everything

the Belay Stop can. They cost

the same, so I’d choose the Two Way because of the faster control

provided by the lever.

The Belay Stop and the SRT Two Way Stop are both protected

by U.S.

Patent 6,029,777.

[ Top

| SRTE v. A

| DB i-SALA 2Way v. A

| DB i-SALA 2Way v. B

| DB i-SALA Double v. A

| DB i-SALA Double v. B

| Return to PolyBollards

]

SRTE Two Way Stop

Version B

(#1121)

Technical Details

I acquired my Single Rope Technique Equipment Two Way Stop, Version A from Jai Andrews in 2013.

The Single Rope Technique Equipment Two Way Stop, Version A is 213 mm. tall, 105 mm. wide, 53 mm. thick, and weighs 825 g. Version B is similar to Version A; here are the main differences:

- The catch and the lever extension are red, not green.

- The steel plate is riveted to the swinging plate is attached with four rivets, not three.

- The bollard on the swinging plate is larger, having the same dimensions as the other two.

- The disarming key was replaced by an acorn nut.

The serial number is 19921501; otherwise, the markings are the same as those on Version A.

The acorn nut is original. Single Rope Technique Equipment’s cut sheet states, "There are two models – one model has an operator-adjustable Disarming Key, and the other model has a non-adjustable Cap-Nut."

The lower hole has a purpose. As the cut sheet says, "In climbing gymnasium conditions, provision has been made to prevent removal of the rope from the SRTE Noworries Two Way Stop by using a 1/4" bolt and lock nut."

The catch and lever extensions refer to two different sizes. Per the cut sheet the rope range is "<11mm red finger grip, to >13mm green finger grip." While this does not specify a precise range (nor should it!), it indicates that the red version (with the larger middle bollard) is for thinner ropes and the green is for thicker ropes. An older catalog from 1997/98 is less ambiguous when it says, "<12mm red finger grip" and ">12mm green finger grip."

[ Top

| SRTE v. A

| SRTE v. B

| DB i-SALA 2Way v. B

| DB i-SALA Double v. A

| DB i-SALA Double v. B

| Return to PolyBollards

]

DBA-SALA Two Way Stop

Version A

(#2564)

Technical Details

I acquired this DBI-SALA NoWorries Two Way Stop from Lance Swartwout in 2020.

This Two Way Stop is 212 mm. tall, 126 mm. wide, 46 mm. thick, and weighs 848 g.

This this DBI-SALA NoWorries Two Way Stop is similar to the SRTE Two Way Stop, Version B. Here are the main differences:

-

The steel plate riveted to the swinging plate has been replaced by an assembly consisting of a spring-loaded "activation plate" and a retaining plate. The activation plate is a stainless steel stamping with three curved slots. The retaining plate is riveted to the swinging plate with two semitubular rivets that pass through the outer slots on the activation plate. A small machine screw passes through the retaining plate, the middle slot in the activation plate, and threads into the swinging plate. I presume that the spring is captured in the central slot by the screw.

The assembly operates much like the fixed steel plate on the earlier versions: the roller on the control lever presses against this plate. When the lever is up, the swinging gate can close. Pulling the lever down cams the swinging plate open, decreasing the friction provided by the bollards. This continues until the lever is in the intermediate position. When the roller passes the nose in the activation plate, rope tension pulls the swinging gate closed, increasing friction. At the same time, the activation plate moves upwards, where it no longer provides an opposing force on the lever. When the lever is released, the mechanism resets without the swing plate opening.

-

There is a new Ascension Pin assembly on the right side of the device. The pin is a stainless steel turned bollard riveted to a connecting linkage made out of 3.1 mm. anodized aluminum alloy. The bollard does not turn, but the linkage pivots on the rear plate. Notches in the side of the front and rear plates allows closing the ascension Pin assembly for storage.

The bottom of the middle bollard has been cut flat. This is the only NoWorries in my collection that has the flat.

- There are no longer any stamped friction areas or markings on the front plate. The arrow and word "OPEN" on the safety catch are the only stamped markings; all others are printed.

The front plate is printed with "GO" and "STOP" over a curved double-headed arrow, "CAPITAL SAFETY," the DBI-SALA logo, "www.capitalsafety.com," "Rollgliss™," "NOWORRIES™," "TWO WAY STOP," "PATENTED," "Max. 200kg," "Min. 30kg," a rigging illustration under the word "UP," "Rope," "O10.5 ≤Ø≤ 12 mm," "Max. 150m," "Min. temp. -38c," "MBS 13kn," "WARNING", "PROPER TRAINING IS ESSENTIAL," a caution icon, and a book-with-an-"i" icon.

The rear is printed with "CAPITAL SAFETY," the DBI-SALA logo, "www.capitalsafety.com," "Rollgliss™," "NW1," "Red," "8700079," "D.O.M. Jun 2013," "SERIAL # 229670-04," the SRTE logo, an SAI Global Certified Product icon, "Australian/New Zealand Standard AS/NZS 4488," "CE 2056," "EN 341-2011," "MEETS NFPA1983 (2005 ED)L," "Made under quality scheme certified by SAI GLOBAL," and "Lic SMKH25365."

The safety catch is stamped "←OPEN."

The Activation Plate assembly "improves" the two-way stop feature by allowing one to reset the lever from the over-travel position without opening the swinging gate, which would reduce friction. I detest double-stop mechanisms, as they are a nuisance that make devices overly sensitive to rope diameter. Competent users do not need these gimmicks, and while some will argue that they make things safer for untrained users, I don't like or allow having untrained users on my trips.

The retaining plate is quite thin, and if dented can keep the activation plate from sliding freely. Similarly, mud or sand can interfere with free motion.

The ascension pin assembly does not appear to be necessary. Its main function, according to the manual, is to allow the NoWorries to function better as an ascender. While it is possible to ascend using the NoWorries as an ascender, the device is decidedly inferior to a proper ascender for ascending.

The flat on the bottom of the middle bollard does not have an obvious purpose and does not seem to affect the NoWorries’ function. For example, the flat does not face the lower bollard so it is not needed for clearance when closing the swinging plate.

Since the NoWorries is targeted at the industrial market, certification is required to keep the lawyers happy. While my academic side likes the various NoWorries devices and they can give very smooth rappels, I find them to be too heavy for practical caving or climbing use.

[ Top

| SRTE v. A

| SRTE v. B

| DB i-SALA 2Way v. A

| DB i-SALA Double v. A

| DB i-SALA Double v. B

| Return to PolyBollards

]

DBI-SALA Two Way Stop

Version B

(#2558)

Technical Details

I acquired this DBI-SALA NoWorries Two Way Stop from Lance Swartwout in 2020.

This Two Way Stop is 212 mm. tall, 112 mm. wide, 46 mm. thick, and weighs 837 g.

DBI-SALA NoWorries Two Way Stop Version B is similar to Version A. The main difference is that the middle bollard is mounted farther in on the swinging plate. In Version B, the swinging plate can close until the middle bollard touches the lower bollard, while on Version A the Activation Plate stops against the roller.

The markings are the same as those on Version A except (1) on the front, the rope range is "12.5 ≤Ø≤ 13.5 mm" and the minimum breaking strength is "MBS 13kn;" and (2) on the rear, the model number is "8700077," the date of manufacture is "Sep 2013," and the serial number is "242428-08."

I noted that devices with two-way stop capability are often overly sensitive to rope diameter. In this case, changing the rope diameter by about one millimeter required moving the middle bollard three millimeters. If the lever was single-acting, the device would work over a wider range of rope diameters, any competent user could easily adapt the friction as desired, and the middle bollard position would not be critical.

[ Top

| SRTE v. A

| SRTE v. B

| DB i-SALA 2Way v. A

| DB i-SALA 2Way v. B

| DB i-SALA Double v. B

| Return to PolyBollards

]

DBI-SALA Double Stop

Version A

(#2557)

Technical Details

I acquired this DBI-SALA NoWorries Double Stop from Janice C. Snowden in 2020.

This Double Stop is 224 mm. tall, 106 mm. wide, 46 mm. thick, and weighs 827 g.

DBI-SALA NoWorries Double Stop Version A is similar to DBI-SALA NoWorries Two Way Stop Version A. Here are the main differences:

- The operating lever is injection-molded plastic rather than laminated aluminum alloy sheets.

- The roller on the lever is farther from the lever pivot.

- The arc in the front plate that clears the acorn nut bolt is larger, with an outer radius of 23 mm. rather than 18 mm.

- The inner plate of the Ascension Pin linkage is larger, so that closing the swinging gate fully forces the linkage open.

- The middle bollard is now a pear-shaped stainless steel casting with a nose at the 4-o’clock position.

- The lower bollard is now pear-shaped as well, lacks a rope groove, and has a nose at the 1-o’clock position.

- The markings on the safety catch are now printed, not stamped.

The front plate is printed with "GO" and "STOP" over a curved double-headed arrow, the DBI-SALA logo, "CAPITAL SAFETY," "www.capitalsafety.com," "Rollgliss™," "NOWORRIES™," "Double Stop," "Descender," "Patented," "Max. 150m (656ft)," "Min. temp. -40c," "•Ø 12.5 - 13mm (1/2")," "MBS 30kn," a caution icon, "WARNING", a book-with-an-"i" icon, "PROPER TRAINING IS ESSENTIAL,"a rigging illustration under the words "ROPE DIRECTION IN DESCENT" and "UP," an SAI Global Certified Product icon with "CE 2056" to the left and "Australian Standard" below, an SAI Global Certified System icon with "Lic QEC0022" " to the left and "Quality ISO 9001" below, "MADE IN AUSTRALIA," "AS/NZS 4488.2-97 Lic SMKH25365," "EN 341:2011/2C Lic. SMK40395," "EN 12841:2006/C Lic. CEPPE50052," "ANSI Z359.4-2013 Lic. SMK40347," "MEETS NFPA1983 (2012 ED) G," "Lic. SMKH25515," "↑," and "USER."

The rear is printed with the DBI-SALA logo, "CAPITAL SAFETY," "www.capitalsafety.com," "Rollgliss™," "NWDS-13," "8700388," "D.O.M. Mar 2015," "SERIAL # 300737-07," "Designed for multiple descents," "Inspect before and after each use by the user and at least annually by a competent person," "Users of this device must read, follow, and maintain copy of the supplied manufacturer’s user manual/instructions," "Use 1/2" (12.5 - 13mm) static kernmantle lifeline. polyester, Nylon, or combination of both materials," "the use of non-compatible rope may result in serious injury or death," "Users must not descend into hazards such as electrical, thermal, or chemical sources," "ANSI Capacity 130lb - 310lb," a weight icon, "Max. 300kg (660lb)," and "Min. 50kg (110lb)."

The safety catch is printed with "←OPEN."

This is not a reflection on DBI-SALA or this device, but the markings illustrate how hopelessly messed up the standards for rope safety equipment are at this time. Just reading the list shows that there are too many standards from too many organizations.

Stating a maximum height of 656ft implies unwarranted precision and demonstrates a lack of understanding of significant digits.

[ Top

| SRTE v. A

| SRTE v. B

| DB i-SALA 2Way v. A

| DB i-SALA 2Way v. B

| DB i-SALA Double v. A

| Return to PolyBollards

]

DBI-SALA Double Stop

Version B

(#2559)

Technical Details

I acquired this DBI-SALA NoWorries Double Stop from Lance Swartwout in 2020.

This Double Stop NWDS-11 8700387 is 224 mm. tall, 106 mm. wide, 46 mm. thick, and weighs 826 g.

The DBI-SALA NoWorries Double Stop Version B is similar to Version A; here are the main differences:

- The roller on the lever is closer to the lever pivot.

- The arc in the front plate that clears the acorn nut bolt is smaller, with an outer radius of 18 mm. rather than 23 mm.

- The middle bollard is about 4 mm closer to the inside edge of the swinging plate.

The markings are the same as those on Version A except (1) on the front, the rope range is "10.5 ≤Ø≤ 12 mm" and (2) on the rear, the model numbers are "NWDS-11" and "8700387," the date of manufacture is "Sep 2015," the serial number is "333100-42," the rope size in the monologue is "Use 1/2" (12.5 - 13mm) static kernmantle lifeline. Polyester, Nylon, or combination of both materials," and the minimum weight is "Min. 30 kg (66lb)."

The acorn nut is original. Single Rope Technique Equipment’s cut sheet states, "There are two models – one model has an operator-adjustable Disarming Key, and the other model has a non-adjustable Cap-Nut."

The lower hole has a purpose. As the cut sheet says, "In climbing gymnasium conditions, provision has been made to prevent removal of the rope from the SRTE Noworries Two Way Stop by using a 1/4" bolt and lock nut."

The catch and lever extensions refer to two different sizes. Per the cut sheet the rope range is "<11mm red finger grip, to >13mm green finger grip." While this does not specify a precise range (nor should it!), it indicates that the red version (with the larger middle bollard) is for thinner ropes and the green is for thicker ropes. An older catalog from 1997/98 is less ambiguous when it says, "<12mm red finger grip" and ">12mm green finger grip."

[ Top

| SRTE v. A

| SRTE v. B

| DB I-SALA 2Way v. A

| DB i-SALA 2Way v. B

| DB i-SALA Double v. A

| DB i-SALA Double v. B

]