Overview

[ Top

| Version B

| Version C

| Return to Double-Stop Bobbins

]

Version A

(#1496)

Technical Details

I acquired my heightec Prism D31, Version A on eBay from the American Alpine Club Store in 2017. Its markings suggest that it was made on June 8, 2011.

Version A is 239 mm. tall, 78 mm. wide, 31 mm. thick, and weighs 510 g.

The two side plates are made of 2.9 mm. aluminum.

One side plate

pivots to allow threading the rope. The lower ends of the side plates

are bent to converge at the attachment point, which consists of

a 16.1 mm. wide, 25.7 mm. high hole on the fixed plate and a hook on the other. Neither of

the attachment points are beveled. The upper portion of the hook is covered by a plastic gate. The gate pivots on a steel rivet, and a spring set in a deep slot

closes the gate. With the gate closed, the opening is only 19.6 mm

high.

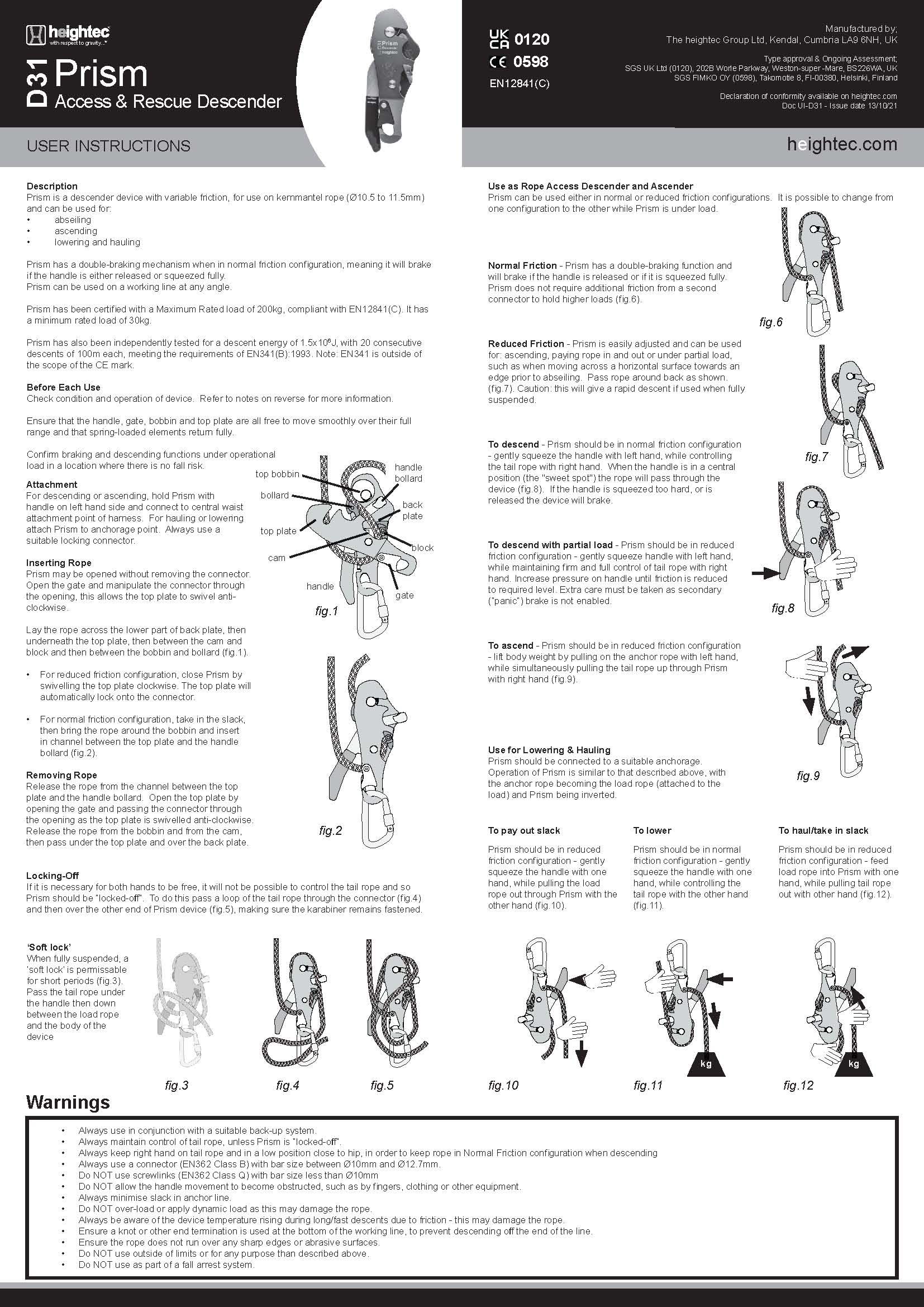

The lower bollard is part of an autostop assembly. It is a stainless steel casting fastened to a handle made from 2.9 mm. aluminum. The lower surface of this bollard has an 11.3 mm. wide, 3.1 mm. deep U-shaped rope groove. The right surface is flat. A 24.8 mm. tall steel anvil is riveted to the rear plate opposite this flat surface. The

handle and front plate pivot on a rivet attached to the fixed side plate side.

The handle has a "rubbery" plastic cover for comfort. Friction from the main rope’s passage tends to

turn the lower bollard and force the flat face towards

the anvil, thus locking the rope and ideally arresting

the descent. The rappeller uses the handle to keep the autostop

feature disengaged. An extension to the handle has a friction block riveted to it. When the handle is squeezed too far, this block forces the rope against the upper bollard.

The upper bollard is turned aluminum. It is 36.3 mm. in diameter with a slight 15.4 mm. wide U-groove that reduces the internal diameter to 35.3 mm. The bollard is eccentrically mounted on a rivet through the side plate, and spring-loaded to rotate counter-clockwise toward an 11.7 mm. pin riveted to the lower left of the bollard.

The pivoting side plate is printed with "D31," "Prism Descender," "080611," "019," "heightec.com," "CE0120," a book-with-an-"i" icon, "EN341:1993 (B)," "EN12841:2006 (C)," "•," "Ø 10.5-11.5," "EN1891 (A)," a human icon, the outline of an up-pointing arrow, "Max 200kg," "Max height 100m," and a rigging illustration. The inside of the rear late is printed with an anchor icon, and arrows and rope illustrations showing the rope path for rigging.

This Prism is well-made, but too heavy for my taste. As much as I dislike auto-stop descenders (for a variety of reasons), I dislike double-stop descenders even more. It is very difficult to design a simple double-stop descender that is not strongly affected by rope diameter. I tried the Prism on 11 mm. PMI Pit rope, a very "standard" American caving rope, and found that it not only had too much friction for my taste (I "weigh" over 90 kg.), but I also had difficulty finding a balance between descending and avoiding actuating the double stop feature. This is not going to be one of my normal caving descenders.

The heightec Prism receive British Patent #2,438,018 in 2007.

[ Top

| Version A

| Version C

| Return to Double-Stop Bobbins

]

Version B

(#3219)

Technical Details

I acquired this heightec Prism D31, Version B from Sam Johnson in 2022. Its markings suggest that it was made on February 3, 2014.

My Version B is 217 mm. tall, 77 mm. wide, 32 mm. thick, and weighs 495 g.

Version B is nearly identical to Version C, except that the shape of the anvil is different. A separate truss-head rivet attaches the anvil to the rear plate. The front of the rivet sits in an enlarged recess in the anvil, where it was expanded by spinning (not pressing) to secure the anvil in place.

The pivoting side plate is printed with "D31," "Prism Descender," the heightec logo, "heightec", and a rigging illustration. The inside of the pivoting plate has printed rope and hand illustrations with hollow arrows to show the rope path. The arrows point opposite the rope's direction of travel through the descender. The rear of the fixed plate is printed with "CE0120," "EN12841C:2006," "•Ø," "10.5-11.5 mm," "EN1891 (A)," a book-with-an-"i" icon, a human icon, "↑," "30 kg - 200 kg," a rectangle containing "EN341:1993 type B" and "Max 100 m (x20)," "030214," a and "1175." The side of the main anvil has a cast illustration of light going through a prism. The friction block has a cast heightec logo.

This version performs the same as Version C. The change to Version C appears to have been made to simplify manufacturing.

[ Top

| Version A

| Version B

| Return to Double-Stop Bobbins

]

Version C

(#3133)

Technical Details

I acquired my heightec Prism D31, Version C from heightec in 2022. Its markings suggest that it was made on November 15, 2021.

My Version C is 218 mm. tall, 77 mm. wide, 32 mm. thick, and weighs 503 g.

The two side plates are made of anodized aluminum.

One side plate

is fixed, the other pivots to allow threading the rope. The fixed plate is 4.0 mm. thick and the pivoting plate is 2.9 mm. The lower ends of the side plates

are bent to converge at the attachment point, which consists of

a 12.3 mm. wide, 24.2 mm. high hole on the fixed plate and a 16.6 mm. wide hook on the other. Neither of

the attachment points are beveled. The upper portion of the hook is covered by a plastic gate. The gate pivots on a steel rivet, and a spring set in a deep slot

closes the gate. With the gate closed, the opening is only 19.4 mm

high.

The lower bollard is part of an autostop assembly. It is a stainless steel casting fastened to a handle made from 4.0 mm. aluminum. The lower surface of this bollard has an 12.3 mm. wide, 3.5 mm. deep U-shaped rope groove. The right surface is flat. A 26.8 mm. tall cast stainless steel anvil is riveted to the rear plate opposite this flat surface. This anvil has a notch near the top that engages one of the slots in the pivoting plate. The handle and front plate pivot on a rivet attached to the fixed side plate side. The handle has a "rubbery" plastic cover for comfort. Friction from the main rope’s passage tends to turn the lower bollard and force the flat face towards the anvil, thus locking the rope and ideally arresting the descent. The rappeller uses the handle to keep the autostop feature disengaged. An extension to the handle has a cast steel friction block riveted to it. When the handle is squeezed too far, this block forces the rope against the upper bollard.

The upper bollard is a round, skeletonized stainless steel casting. It is 36.5 mm. in diameter with a slight 15.3 mm. wide U-groove that reduces the internal diameter to 4.1 mm. The bollard is eccentrically mounted on a rivet through the side plate, and can rotate counter-clockwise toward a cast steel anvil riveted to the lower left of the bollard. The head of this rivet extends outside the pivoting plate, and a circumferential groove in the head fits into the upper curved slot in the pivoting plate. A pin extension on the rear of the bollard fits into a curved slot in the fixed plate, limiting the bollards motion in both directions.

The pivoting side plate is printed with "D31," "Prism Descender," the heightec logo, "heightec", "Patented, and a rigging illustration. The inside of the pivoting plate has printed rope and hand illustrations with hollow arrows to show the rope path. The arrows point opposite the rope's direction of travel through the descender. The rear of the fixed plate is printed with "UKCA," "0120," "CE0598," "EN12841C:2006," "•Ø," "10.5-11.5 mm," "EN1891 (A)," a book-with-an-"i" icon, a human icon, "↑," "30 kg - 200 kg," a rectangle containing "EN341:1993 type B" and "Max 100 m (x20)," and "151121." It is stamped with "D0583." The side of the main anvil has a cast illustration of light going through a prism. The friction block has a cast heightec logo.

This Prism is well-made, but too heavy for my taste. In my test, the double-stop feature on this version performed worse than the one on Version A. Once again, I tried the Prism on 11 mm. PMI Pit rope, a very common (and my favorite) American caving rope. Not only was it difficult to get the rope into this Prism, but once rigged, it gave too much friction for me to move. I could remove the rope from underneath the double-stop friction block and use the Prism like a normal stop bobbin, but what's the point? Do not try this yourself, lest the rope slip off the top of the Prism. It requires some care to keep the rope in place, albeit less than required for the Dressler DAD.

[ Top

| Version A

| Version B

| Version C

]