Technical Details

I acquired my Beal (ISC) D4 from Expé-Spelemat in 2016.

The Beal (ISC) D4 is 197 mm. tall, 82 mm. wide, 78 mm. thick, and weighs 681 g.

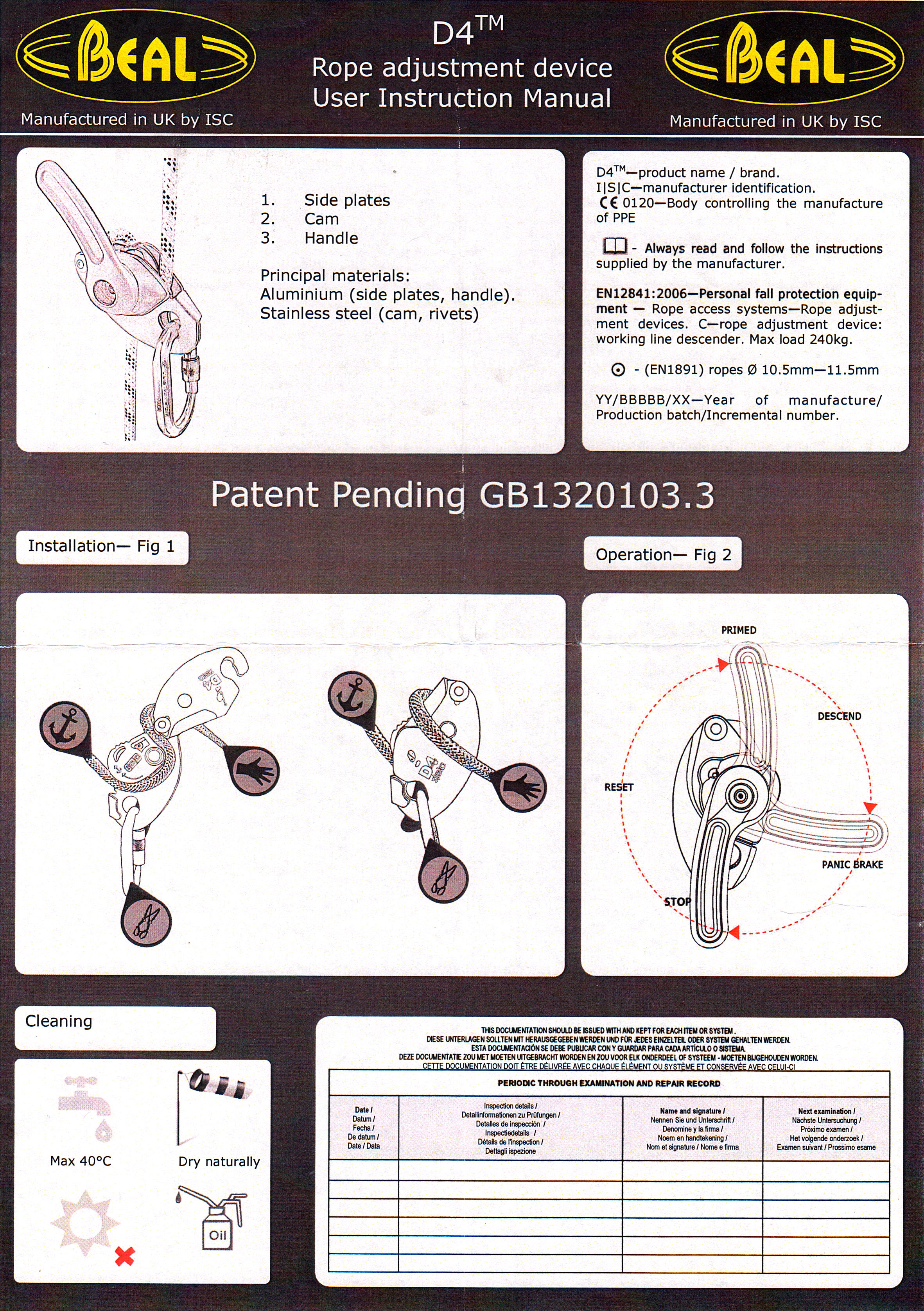

The D4 is shaped like an American football

with a handle on the back. There are two stamped aluminum plates

with a variety of other parts attached. The rear plate is

gold anodized 3.9 mm. aluminum, and serves as the main frame.

A 21 by 29

mm irregular opening in the lower portion serves as the clip-in eye. The plate is bent forward at the lower left, forming a hook that overlaps the outside of the front plate.

The rear plate has several components mounted on it. Starting

from the top, there is a 14.8 mm. long, 21.8 mm. major diameter U-groove bollard. The bollard has a 17.8 mm. minor diameter. The rivet bolding the bollard in place also serves as the pivot for the front plate. Below the bollard is a pivoting stainless steel cam mounted on an axle and bearing. The axle has a spring-loaded plunger in the end that serves to lock the front plate closed. Most of the cam’s circumference

is grooved to guide the rope. There are also what appear to be four teeth, but these serve no function in this device. The upper side of the cam is flattened so that the rope can run between it and the

upper bollard. The

main bollard can be rotated about 20 degrees using the handle.

Rotating the bollard clockwise squeezes the rope against the anvil,

stopping the descent.

The handle assembly is attached to the rear plate by four screws, one of which also secures the cam axle.

The front plate is mounted and pivots on the upper bollard post. The left side is bent back on itself to create a rounded edge

for the rope to run against. The left side is raised so that it

clears a slot that engages a rim on the main bollard pivot. A J-notch on the lower portion

of the front plate lines up with the oval hole on the rear plate.

The notch admits the seat maillon.

The normal rigging path is to bring the rope down the left side, under

the cam, up between the cam and upper bollard, then out the top and over the bend in the front plate. The

rope path is much like the classic bobbin rope path.

The cam is turned by the handle on the rear of the

device. A clutch

assembly controls the motion. The clutch is not visible without

destroying the device. When viewed

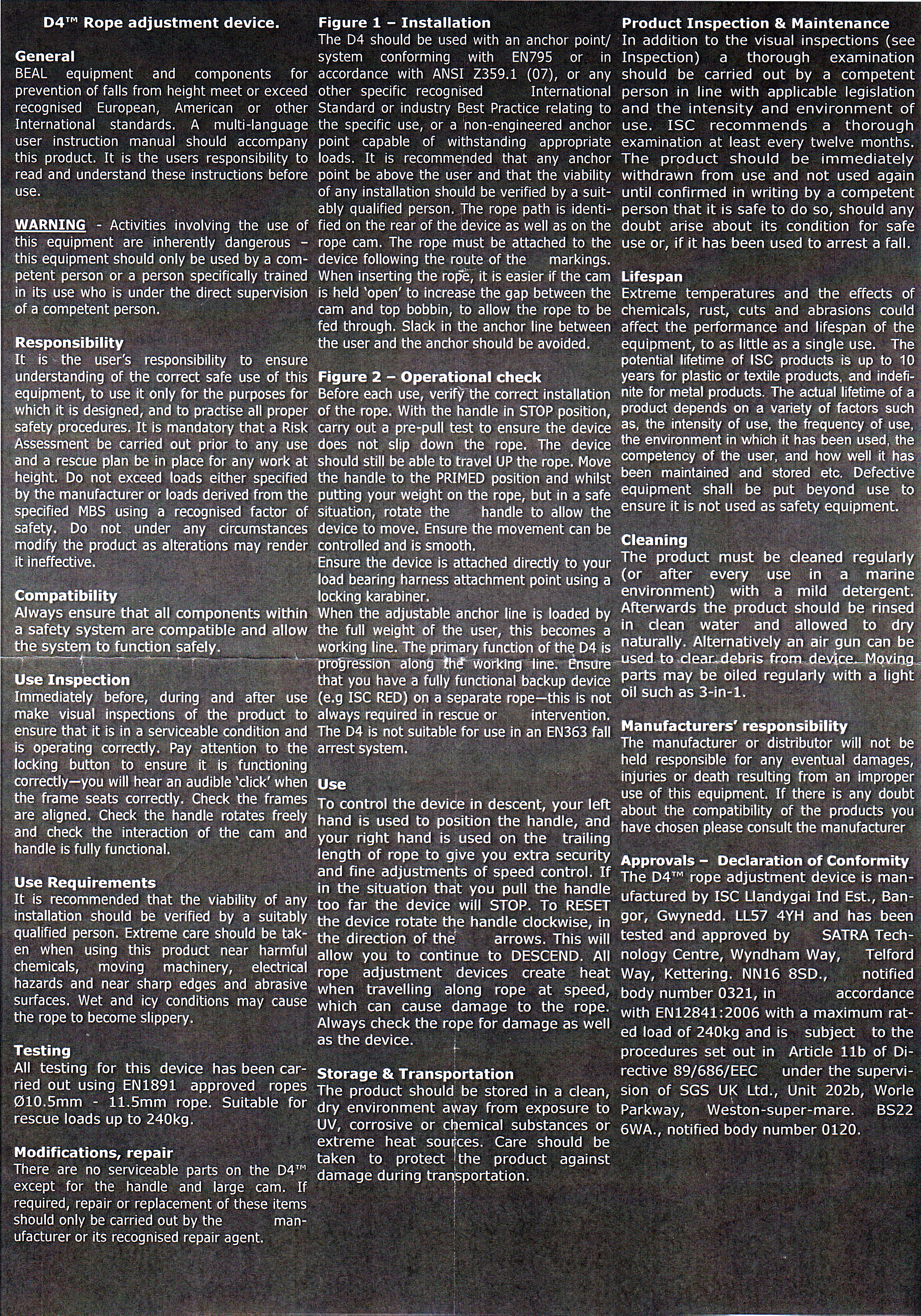

from the front, the normal descending position is with the handle

at 9 o’clock. The rope friction is turning the cam so that

the rope is squeezed against the anvil. Pulling down (counter clockwise)

on the handle turns the main bollard counterclockwise, which releases

the rope. If the handle is moved too far, the clutch slips and

the bollard rotates back to the locking position (clockwise). Turning the handle clockwise from 7 o’clock to 10 o’clock resets the mechanism without affecting the cam’s position.

The front plate is stamped with the Beal Logo, a rigging illustration, a D4 Descender logo,

"Made in the UK by I|S|C," "0175 07/16," a book-with-an-"i" icon, "CE0120," "Rope • Ø10.5-11.5 mm," "EN12841:2006/C," "100m (60kg-240kg)," "77416," "MEETS NFPA 1983(2012 ED), "MBS 16kN ’T’," "ANSI Z359.4:2013," and "Patent Pending." The rear of the handle is printed with "D4." The cam has an anchor icon, a curved arrow, and "I|S|C" cast into it.

The D4 reminds me of the Petzl I’D, although there are significant differences. I wouldn't want to expose the clutch to abrasive cave mud. I'm not a fan of stop descenders

for a variety of reasons,

but this one is fun to play with.

The instructions are slightly confusing since they show the handle motion viewed from the opposite side as what the user sees, but that is a minor point - just be aware of it when you read the instructions before first using the D4.