Overview

[ Top

| Sanko

| Return to Rope Grabs

]

Fuji-Denko B-02 Titan 9502781

(#3712)

Technical Details

I acquired my Fuji-Denko B-02 Titan 9502781 from Marine Federation in 2022.

My Fuji-Denko Titan is 109 mm. tall, 94 mm. wide, 50 mm. thick, and weighs 688 g.

The Titan consists of a U-shaped body stamped from 2.3 mm. steel,

a cam built from four 2.9 mm. steel stampings laminated together,

and an attachment eye made from a 6 mm. steel stamping. A 32 mm. long lanyard made from 11 mm. laid nylon rope connects the rope grab to a double-action snap hook. Most of the metal pieces are chrome plated.

The body is a 94 mm. high, U-shaped stamping with a 21 mm. wide

rope channel. The rope channel is flared outward at the top. The right side

is rolled backward on itself and welded to form a cylindrical

channel for a 7.8 mm. diameter steel rod that acts as a closure

latch for the cam assembly. A 12 mm. high notch admits a 10 mm.

pin attached to the cam. This pin acts as the cam axle. A spring holds the closure latch closed.

A pin on the side of the closure latch lets the user pull the

latch open to admit the cam pin. A gravity plate hinged

to the rear of the body blocks this pin motion to prevent accidental

opening. The left side of the body has two tabs that are rolled backward

on themselves and welded to form a cylindrical channel for an 8 mm.

pin. The cam assembly hinges outward on this pin to open the Titan

for rigging.

The body is a 94 mm. high, U-shaped stamping with a 21 mm. wide

rope channel. The rope channel is flared outward at the top. The right side

is rolled backward on itself and welded to form a cylindrical

channel for a 7.8 mm. diameter steel rod that acts as a closure

latch for the cam assembly. A 12 mm. high notch admits a 10 mm.

pin attached to the cam. This pin acts as the cam axle. A spring holds the closure latch closed.

A pin on the side of the closure latch lets the user pull the

latch open to admit the cam pin. A gravity plate hinged

to the rear of the body blocks this pin motion to prevent accidental

opening. The left side of the body has two tabs that are rolled backward

on themselves and welded to form a cylindrical channel for an 8 mm.

pin. The cam assembly hinges outward on this pin to open the Titan

for rigging.

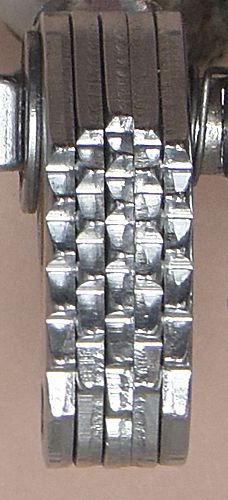

The cam is made from four stampings. One of these is bent into a "U" to form the outer two laminations, giving five total. This stamping acts as the cam arm, and the "U" forms a channel for the attachment eye. The cam laminations have z-shaped teeth cut to form

the cam face: seven on the center lamination and six on each of

the others, not counting a long extension at the cam toe. The

cam pivot has a hole at one end where the 7.8 mm. hinge pin goes.

The other end extends through the cam and the latch block mentioned

in a previous paragraph. A spring tends to close the cam. One

end of the spring loops around a pin riveted in the side of the

cam, the other fits under a Phillips screw head in the latch block.

There are rivets near the cam axle and cam toe to hold the cam laminations

together.

The left side of the Titan is stamped with "2015-04" and "S-SLIDE." There is a sticker with Japanese text that I can neither read not type. The right side is stamped with a hollow up-pointing arrow with "UP" and "上" inside. The spine is stamped with some Japanese text, "ø18mm - ø18mm," more Japanese text, "FORø18mm - ø18mm NYLON or POLYESTER ROPE," "B-02," and "TITAN." The release tab is stamped with "PUSH." The snap hook is stamped with the Sanko-Titan logo, "B-02," and "MADE IN JAPAN" on one side, and "TITAN" on the other.

The Fuji-Denko Titan is typical of the stamped-metal rope grabs. It uses

a laminated cam like several others. The steel construction makes

it too heavy for caving or climbing use, and the complex operating

mechanism makes it difficult to operate one-handed.

[ Top

| Fuji-Denko

| Return to Rope Grabs

]

Sanko Ind. Co. Ltd. Titan

(#883)

Technical Details

I acquired my Sanko Titan from Paul Brian Scurr in 2006.

The Titan consists of a U-shaped body stamped from 2.5 mm. steel,

a cam built from five 3 mm. steel stampings laminated together,

and an attachment arm made from two 3 mm. steel stampings, plus

a number of minor components, Most of the pieces are chrome plated.

The body is a 104 mm. high, U-shaped stamping with a 22 mm. wide

rope channel. The rope channel is flared outward at the top and

bottom. The body is 55 mm. wide. The right side

is rolled backward on itself and welded to form a cylindrical

channel for an 8 mm. diameter steel rod that acts as a closure

latch for the cam assembly. A 13 mm. high notch admits an 11 mm.

pin attached to the cam. A spring holds the closure latch closed.

A pin on the side of the closure latch lets the user pull the

latch open to admit the cam pin. A spring-loaded plate hinged

to the rear of the body blocks this pin motion to prevent accidental

opening.

The left side of the body has two tabs that are rolled backward

on themselves and welded to form a cylindrical channel for a 7 mm.

pin. The cam assembly hinges outward on this pin to open the Titan

for rigging. The cam laminations have z-shaped teeth cut to form

the cam face: seven on the center lamination and six on each of

the others, not counting a long extension at the cam toe. The

cam pivot has a hole at one end where the 7 mm. hinge pin goes.

The other end extends through the cam to engage the latch mentioned

in the previous paragraph. An external retaining clip (E-clip)

holds the cam on the pin. A spring tends to close the cam. One

end of the spring loops around a pin riveted in the side of the

cam, the other fits under a Phillips screw head in the cam axle.

There is another rivet near the cam toe to hold the cam laminations

together.

The three central cam laminations extend 70 mm. from the cam

pivot to form the cam arm. A central rivet extends to form a pin

on the right side that limits how far the cam can open or close.

The attachment arm consists of two more laminations riveted

together at their base. Each is bent outward to sandwich the two

sides of the cam arm. A rivet forms a pivoting attachment. There

are two tie-in holes. The larger is 20.3 mm. and the smaller 16.5 mm.

The larger hole is closer to the main rope.

The left side of the Titan is stamped "9111937 PAT."

and "SANKO IND.CO. LTD." The right side is stamped with

an up-pointing arrow and "UP," "ROPEØ16,"

"TITAN," "SLIDE CHUCK," "90-1,"

and "TYPE 82."

The Titan is typical of the stamped-metal rope grabs. It uses

a laminated cam like several others. The steel construction makes

it too heavy for caving or climbing use, and the complex operating

mechanism makes it difficult to operate one-handed.

[ Top

| Fuji-Denko

| Sanko

]