Overview

Mike Cowlishaw described[1] the Neill Box in 1978, saying that it was "the fourth best thing to come out of Ireland (after Guinness, women, and song)" and that it was "[d]eveloped by Maurice Neill a couple years ago."

Mike Cowlishaw described[1] the Neill Box in 1978, saying that it was "the fourth best thing to come out of Ireland (after Guinness, women, and song)" and that it was "[d]eveloped by Maurice Neill a couple years ago."

The Neill Box shown in the figures accompanying Mike's article differs from the versions in my collection,

|

|

If you have a version that I am missing and are willing to part with it, please email me. |

|

[1] Cowlishaw, Mike, 1978. "The Neill Chest Box." Descent, v. 39, pp. 36-37

[ Top

| Version B

| Return to Chest Boxes

]

Version A

(#640)

Technical Details

I acquired this Neill Box from Speleoshoppe in 1979.

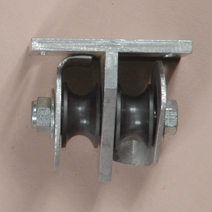

The box consists of a frame, two rollers, an axle, two side

plates, and miscellaneous parts. The frame is made from a T-shaped

aluminum extrusion, cut to 63.7 mm. length. The crossbar on the

T is 76.2 mm. wide and the stem is 62.2 mm. long; each is 6.4 mm.

thick. The cross piece of the T forms the back of the box, and

rests against the climber’s chest. The back has a 51 mm. tall,

5 mm. wide slot milled in each side to accept a chest harness.

The top of the stem is cut off at a bout a 45° angle for about

45 mm. The bottom is rounded on a 32 mm. radius circular arc centered

on the axle centerline. This arc is not tangent to the bottom

of the box.

The axle is a 71 mm. long, 3/8" (9.7 mm.) hex-head bolt.

The bolt passes from the climber’s left to right through a flat

washer, the left side plate, left roller/bushing, frame, right

roller/bushing, right side plate, another flat washer, and finally

a nylon lock nut. Each roller is made from hard gray plastic.

The rollers are 17.9 mm. wide and have a major diameter of 32.2 mm.

Each roller has a centered 14.2 mm. U-shaped groove turned in it

to a depth that gives a 19.4 mm. minor diameter. The rollers ride

on a steel bushing that is about 20.5 mm. long and 19.2 mm. in diameter.

Since the rollers fit the bushing tightly and are centered, they

do not rub against the side plates or frame.

Each side plate is made from an irregular piece of 2.8 mm. aluminum.

The top half of a side plate is a 25.4 mm. circular arc, the lower

front is cut at 45° angle, and the lower rear has a flat base

and an extension that is curved inward to fit just forward of

the frame.

There are no markings on the device except for "C,"

"l," and "R" on the bolt head

The Neill Box is a simple British box. The rope channels can

be opened independently by simply pivoting the side plates. There

are no catches to hold the plates closed.

On April 22, 2008, I received a nice

email from Ivan Young, who informed me that my picture was upside

down (I've since revised all the photos on this page). Ivan wrote the following:

"I used a Neill Box - Version A (1977 vintage) - and still have it. I've also a Version B in

my collection (1978) that used to belong to one of my friends.

Your front view photograph of them is upside down. If you tried

using them in that orientation the side plates swing open and

would rub on the rope all the time. The other way up their weight

holds them against the back plate and (mostly) away from the

rope. That also puts the ’top’ slot in Version B at the bottom.

I guess that is to rig a safety line down to the sit harness

but I can't remember my friend ever using it. So you need to

turn your photos round and rewrite the description."

The photo that he referred to was similar to the

alternate view shown above. "Obviously" he was right, which I readily

admitted (After all, this is how I mounted them in the 1995, 2000, and 2007

NSS Convention displays), but then

he wrote back:

It’s not just the photos that are upside down. So is the explanation of use.

That got me thinking that I couldn't have been

completely crazy when I first wrote this page - there had to

be something more. There was. Ivan is quite likely right about

the way the Neill box was designed to be used, but what I had

found long ago was another way to use the Neill Box which, for

my rig, works better for me (your mileage may vary). Most of my

original description stands, but I'll include some of Ivan’s comments

in blue, with my replies in green.

The climber has two ways to use the side plates when the box is inverted (alternate arrangement), as follows:

The

first method is the fastest for inserting or removing

a rope from the box, and uses the alternate (upside-down) rigging

with the channels used as shown on the right side (climbers left)

in the photo at right. In this arrangement, the user pivots

the side plate until the 45° cutout is toward the frame and

vertical, then slides the rope into place. Gravity pulls the

bent portion of the side plate downward, closing the gap. The

rope is now held in place, but not securely. Note that rope drag

tends to open the box.

The

first method is the fastest for inserting or removing

a rope from the box, and uses the alternate (upside-down) rigging

with the channels used as shown on the right side (climbers left)

in the photo at right. In this arrangement, the user pivots

the side plate until the 45° cutout is toward the frame and

vertical, then slides the rope into place. Gravity pulls the

bent portion of the side plate downward, closing the gap. The

rope is now held in place, but not securely. Note that rope drag

tends to open the box.

Only if you are wearing the box upside

down!!! Right way up there is hardly more than the groove in

the pulley to keep the rope from popping out. I think this would

be far too exciting a method for me and as I wrote in my previous

message I have never heard of this method ever being used. Your

website is the only place I've read of it.

Perhaps I invented this way of using

the box upside down.

|

|

Warning:

This

method allows the rope to easily and accidentally come out of

the box. |

|

|

This isn't a common problem but it can happen, so be sure

that your climbing system can handle this. One nice feature of

this method is that one can remove a loaded rope from the box,

a nice feature for Mitchell System climbers when they reach the

lip, when the main line is under tension.

That is one of the reasons I grew to

hate my chest box! I couldn't easily remove it from the main

rope so non-free-hangs were a pain in the chest.

This method works better for me than

the original method does, although I admit that the curved sides

sometimes "catch" on the slings. I use a Cuddington

3-phase climbing system, and this means that I expect to"come

out of the box" at least once on every climb. That is quite

easy using this method and quite difficult, by comparison, using

the method described in the next bullet. You can place the curved

section behind the rope or sling (from below), although it will

drag slightly as the rope/sling moves downward. Mitchell climbers

might like doing this with the ascender sling rope, since one

rarely removes this one from the box - and when one has to. lifting

the foot provides all the necessary slack. Perhaps the best option

of all is to replace the rope-side plate with a custom plate

that lacks the bend, and then use the box right-side up.

- The second (original) method is more secure. It uses the

original (right side up) rigging with the the channels used as

shown on the left side (climbers right) in the photo associated with the previous bullet. In this arrangement, the user starts like before and pivots

the side plate until the 45° cutout is toward the frame and

vertical, then slides their sling into place. The user then bends

the rope/sling forward and downward, and slides it inside the

curved lip on the side plate (which is aligned with the 45°

cutout at the top front of the frame). Straightening the sling

rotates the plate closed with the curved portion of the side

plate behind the sling. The side plate cannot be opened without

bending the rope/sling enough to reverse the process, so the

sling remains effectively locked in place. Using this method

provides extra security but makes coming out of the box rather

difficult.

As far as I am concerned this is the

only method for both rope and foot sling. It is a pain having

to haul up enough slack on the main rope to free it from the

box, but (unless the nut drops off!) it just cannot disengage

from the box by itself.

I cannot argue against someone else’s

preference, but I have shown that there is an alternative. My

rig has a safety strap (as it should), so box failure isn't something

that I worry about.

Ivan, Thank You for your comments!

Overall, I think that the Neill Box is a clever design. Each

of the cutouts and curves has a specific function, and they work

together nicely. On the other hand, I prefer somewhat more security

against the main line accidentally opening my box. I also like

a wider box, since I'm willing to trade some bulk and weight for

improved harness efficiency.

[ Top

| Version A

| Return to Chest Boxes

]

Version B

(#823, 2600)

Technical Details

I acquired this box from Brian Trevelyan on eBay in 2005. I acquired another in 2017 as part of Bob Thrun’s collection.

The description is similar to Version A’s, so I'll note the

differences in red:

The box consists of a frame, two rollers,

an axle, two side plates, and miscellaneous parts. The frame is

made from a T-shaped aluminum extrusion, cut to 76.2 mm. length. The crossbar on the T is 76.2 mm. wide

and the stem is 52.1 mm. long; each is 6.4 mm. thick. The cross piece

of the T forms the back of the box, and rests against the climber’s

chest. The back has a 52 mm. tall,

7 mm. wide slot milled at a 45° angle (front to back) in each side and

a centered 26.5 mm. wide, 7 mm. high top slot

to accept a chest harness. The top of the stem is cut off at a

bout a 45° angle starting just

below the top slot. The bottom is

rounded on a 19.3 mm. radius circular arc centered on the axle centerline.

This arc is tangent

to the bottom of the box.

The axle is a 71 mm. long, 5/16" (8 mm.) steel rod threaded on both

ends. The bolt passes from the climber’s

left to right through a hex nut, flat washer, the left side plate, left roller/bushing,

frame, right roller/bushing, right side plate, another flat washer,

and finally another hex nut. The

ends of the rod are crudely chiseled and punched to keep the nuts

in place. Each roller is made from

hard gray plastic. The rollers are 16.2 mm. wide and have a major diameter of 25.8 mm. Each roller

has a centered 11 mm. U-shaped groove turned in it to a depth that

gives a 21.6 mm.

minor diameter. I don't see a ny

roller bushings, and the rollers do

rub against the side plates and frame.

Each side plate is made from an irregular

piece of 2.8 mm. aluminum. The top half of a side plate is a 25.4 mm.

circular arc, the lower front is cut at 45° angle, and the

lower rear has a flat base and an extension that is curved inward

to fit just forward of the frame.

There are no markings on the device.

Although essentially unused, this is much older than

the 2005 acquisition date suggests. I recall seeing a virtually

identical Neill Box at the NSS Vertical Section meeting at our

1978 convention - even the color is the same. I am fairly certain that that box was the one that I later acquired as part of Bob Thrun’s collection.

Aside from the finish and dimensional differences, this box

has two features missing on Version A: the horizontal slot and angled

side slots. Neither is essential. I don't need the slot with

my harness, but I like the angled side slots since it makes it

easier to adjust the lateral position of the box on my harness.

This Neill Box was made by Goldlock.

[ Top

| Version A

| Version B

]