Nevin Davis' Original M.A.D.

(M.A.D. Mark III)

(#110)

Nevin

Davis made the first MAD, or Motorized Ascending Device. This was

the first and perhaps only motorized ascender whose details were

widely published. Others made earlier claims but never published

many details (e.g., one never even mentions what the power source

was) so I tend to discount them. The M.A.D., however, was well-documented,

and certainly exists. I bought the original MAD from Nevin at the 1989 Old Timers Reunion. Without a doubt, this is the

most complex, and most interesting item in my collection.

Nevin wrote that the MAD was developed for people who

"do not view vertical caving as an end in itself but instead

want only to visit the cave at the pit bottom and then exit in

the most comfortable manner." I've spoken to Nevin and feel

that there was a second motive: to show that it could be done,

and to illustrate that some of the people who had speculated about

motorized ascenders had underestimated some of the problems. When

he built the MAD, Nevin proved that the engineering difficulties

could be overcome.

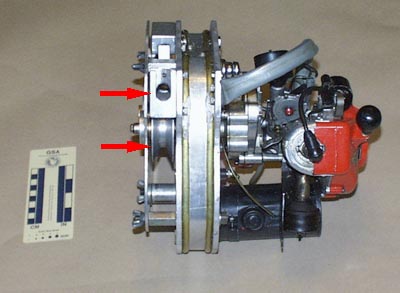

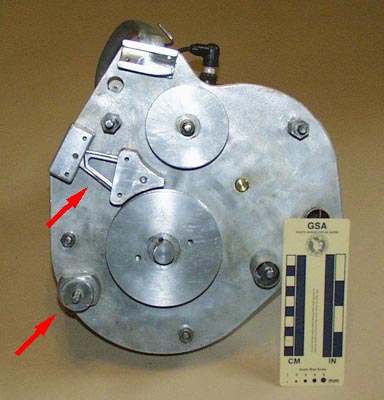

I acquired Nevin's original M.A.D. Mark III from Nevin in 1989. The M.A.D. Mark III is 330 mm. tall, 280 mm. wide, 280 mm. thick, and weighs 10400 g.

The engine side. Note the handgrip.

The MAD is powered by a one horsepower Olsen and Rice gasoline

engine. The engine has an integral centrifugal clutch and gear

box. Further gear reduction is provided by a set of lathe change

gears contained in a fabricated gearbox. The original MAD had

a motor-cycle grip throttle, but this was later replaced by a

smaller and lighter handgrip. A "kill" switch completes

the controls.

|

Top View, showing upper rope guide and idler

pulley.

|

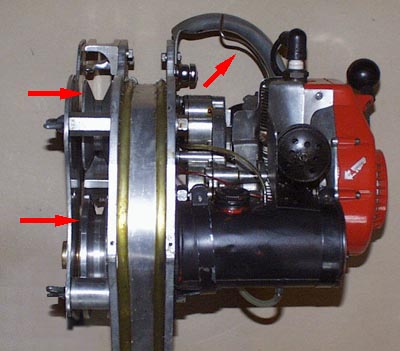

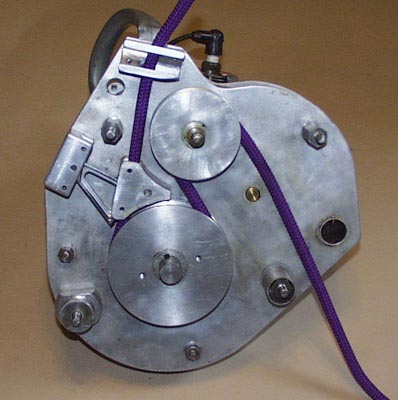

Front view, showing drive & idler pulleys and hand throttle.

|

The is threaded much

like an old-fashioned movie projector - i.e., you have to take

a cover plate off and feed the rope by hand. The rope enters the

top of the MAD through a machined rope guide. From there it passes

a Jumar cam that keeps the MAD

from sliding down the rope when the engine is stopped or idling

with the clutch disengaged. Next it loops around the drive pulley.

Finally it passes around an idler pulley that directs the rope

downward and out of the MAD.

The is threaded much

like an old-fashioned movie projector - i.e., you have to take

a cover plate off and feed the rope by hand. The rope enters the

top of the MAD through a machined rope guide. From there it passes

a Jumar cam that keeps the MAD

from sliding down the rope when the engine is stopped or idling

with the clutch disengaged. Next it loops around the drive pulley.

Finally it passes around an idler pulley that directs the rope

downward and out of the MAD.

The drive pulley has a V-shaped groove with a 30° included

angle. This angle is critical, if it is too large it won't grip

the rope, while if it is too small there will be too much friction

and the rope will bind in the pulley. Nevin designed the pulley

for Goldline and Samson 2-in-1, which were the primary caving

ropes when the MAD was built. I think that a smaller angle is

needed for the modern, stiffer caving ropes, because I find the

MAD slips on them unless one hangs about 15 kg (30 pounds) on

the rope. Nevin's articles suggested one third that amount for

the older ropes.

Opened ascender, showing safety cam and clip-in

point.

|

Ascender with rope threaded.

|

Climbing with the MAD is, well, unique. Fill the gas can first

- omitting this step might leave you 800 feet off the pit floor

with a 22-pound ascender to haul out. Attach the ascender to the

rope, and clip your seat harness to the attachment point. Most

people will also want a chest harness to hold them upright. Pull

the cord to fire the engine. At idle, the centrifugal clutch will

disengage, and you'll be hanging from the Jumar

cam. Its best to have a backup (float a Gibbs)

in case the cam fails, otherwise terminal velocity is determined

by the gearbox friction and lubricant viscosity. Add power, and

you're off. Motor to the top, walk the edge, and hit the kill

switch. With the MAD, you'll be out of El Sótano de las

Golondrinas in 25 minutes, just a couple minutes behind the faster

cavers, but hours ahead of the tourists.

| Specifications |

| Weight |

10 kg |

21.5 lbs |

| Engine |

750 Watt |

1 Hp |

| Fuel Consumption |

860 meters per liter |

2 miles per gallon |

| Engine Accessories |

6921:1 Integral Compound

Gear Reduction and Steel Centrifugal clutch |

| Maximum Engine Output Shaft

Speed |

900 rpm counter-clockwise |

| Gearbox Reduction |

High Gear |

12:1 |

| Low Gear |

24:1 |

| Maximum Load |

High Gear |

90 kg |

200 lbs |

| Low Gear |

180 kg |

400 lbs |

| Speed |

High Gear |

23 meters per

minute |

74 feet per minute |

| Low Gear |

11 meters per

minute |

37 feet per minute |

These

construction details are from Nevin Davis' article Motorized

Ascending Device MAD in The Nylon Highway #19:

|

| Item |

Description |

| A |

Rope guide, 6061-T6 |

| B |

Jumar cam pivot block, 6061-T6 |

| C |

Jumar Cam |

| D |

Cam Backing block, 6061-T6 |

| E |

"Vee drive pulley, 30° angle is critical,

6061-T6 |

| F |

Idler pulley, 6061-T6 |

| G |

Twist grip throttle & cable, later replaced |

| H |

Suspension bar, aluminum |

| I |

Spacer bars, steel |

| J |

Spur gear, Boston Gear #NB16B |

| K |

Lathe change gear, Boston Gear #GB80 |

| L |

Lathe change gear, Boston Gear #GB20 |

| M |

Lathe change gear, Boston Gear #GB96 |

| N |

Collar, brass |

| O |

Rope cover plate, 6061-T6 |

| P |

Intermerdiate gearbox cover plate, 6061-T6 |

| Q |

Outside gearbox cover plate, 6061-T6 |

| R |

Tank mounting bracket |

| S |

Motor mounting holes |

| T |

Motor output shaft |

| U |

Gearbox grease seal, 5053 aluminum & tygon

tubing |

| V |

Angled grease fitting |

| W |

Drive shaft, steel drill rod |

| X |

Intermediate idler shaft, naval bronze |

| Y |

Output shaft, steel drill rod |

| 1,3 |

Flanged bearing, Boston Gear #FB-811-4 |

| 2 |

Straight sleeve bearing, Boston Gear #B811-8 |

| 4, 6 |

Thrust bearing, Boston Gear #TB-814 |

| 5 |

Compound steel bushing, Boston Gear #GBB-18 |

| 7, 8, 9 |

Flanged bearing, Boston Gear #FB-1216-6 |

| 10, 11 |

Woodruf keys |

| Motor |

Olsen and Rice Engines Type 204(T-111) |

|

|

|

Believe it or not, the 1971 parts cost for the M.A.D. was only

$120 U.S!

For far more content, use a larger monitor and a full-width window.

Hundreds of cell phone users complained and asked me to for a simpler, mobile friendly site. In particular, they wanted me to limit each page to a small number of pictures and minimize my use of text. This new site provides what they asked for.