Technical Details

I acquired my Notch Equipment Rope Runner Pro from TreeStuff.com in 2021.

The Notch Equipment Rope Runner Pro is 158 mm. tall, 97 mm. wide, 45 mm. thick, and weighs 429 g.

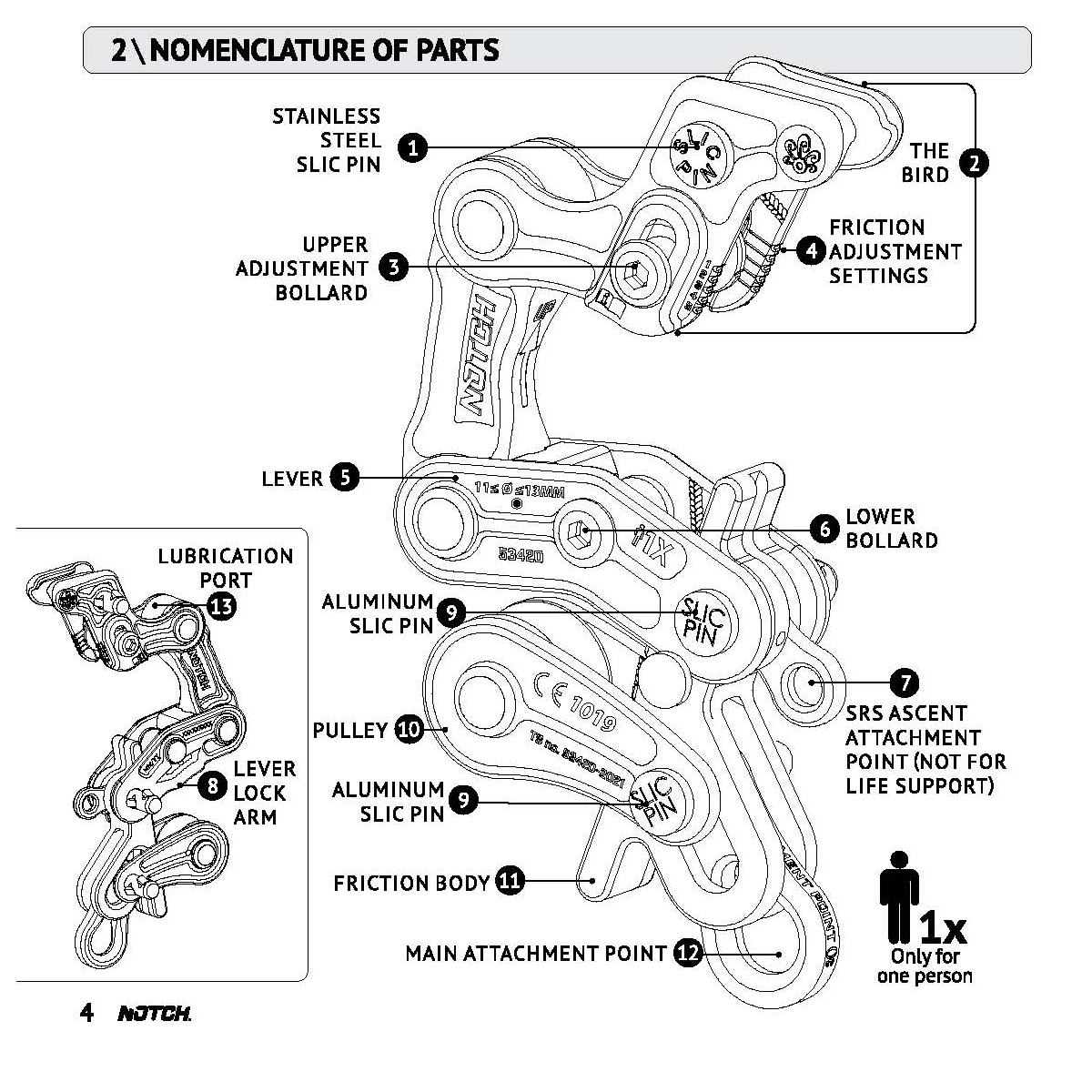

The Rope Runner consists of five pieces connected by removable pins, dual-shoulder bolts, and the user’s attachment carabiner. Starting at the top, the main pieces are as follows:

- Bird: The Bird consists of two parallel dog-leg aluminum forgings. At the distal end is a double-acting stainless steel slic pin that can be removed to admit the rope. On the dog-leg portion is an adjustable friction bollard that can be moved within rectangular slots in the side plates. The lower end is connected to the Tether assembly by a shouldered axle riveted in place.

- Tether Assembly: The Tether assembly consists of a forged aluminum link. The dual-shoulder bolt connecting it to the Bird has a spring around it, with an arm of the spring engaging a small hole in the tether. The Tether completely encloses the spring. The other end of the spring probably engages a hole in the bolt, but this is not visible. The bolt rotates with the Bird. The spring acts to extend the Bird. The other end of the Tether is connected to the Lever Assembly with another riveted shouldered axle.

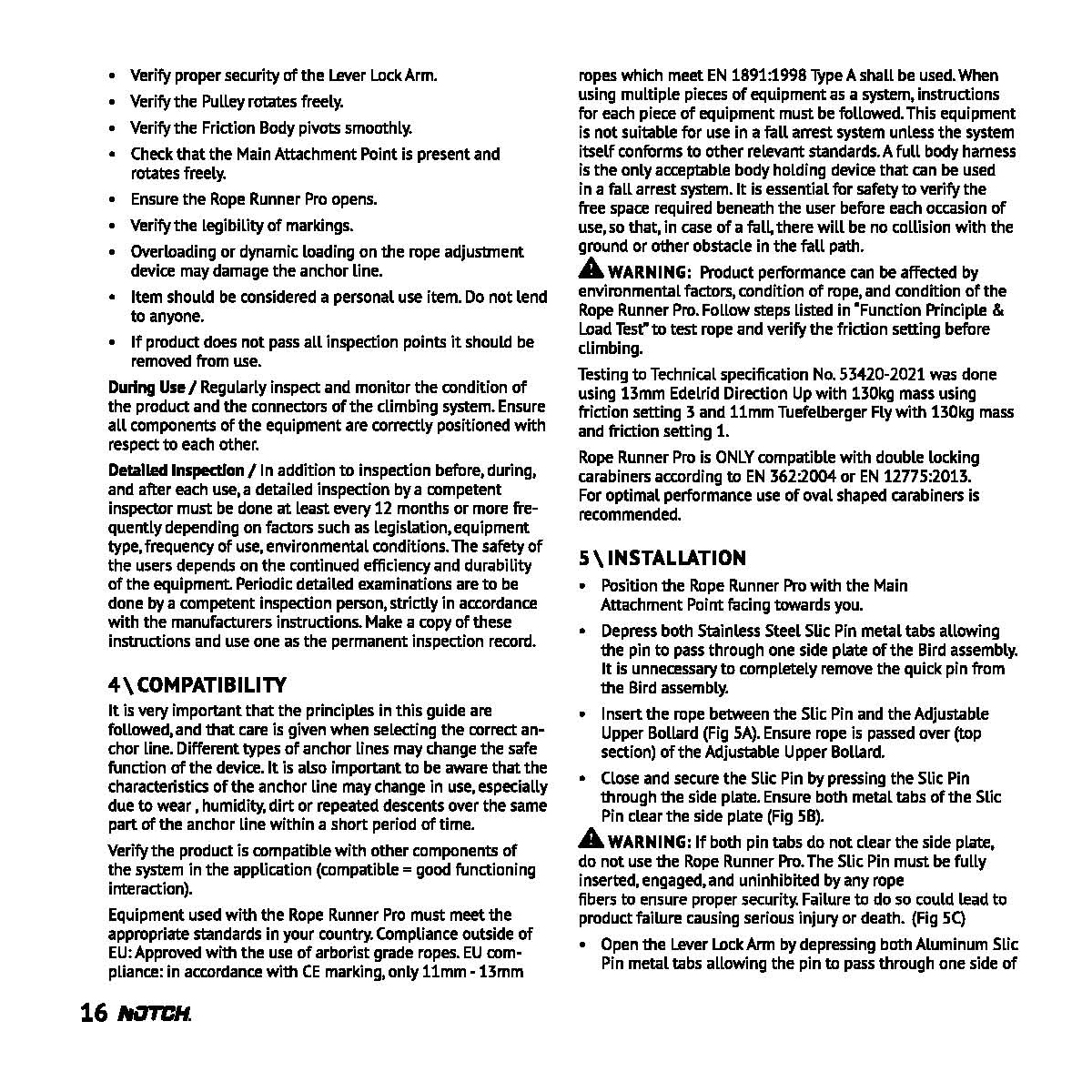

- Lever Assembly: This consists of two slightly angled forgings. In addition to the shoulder bolt connecting the Lever to the Tether Assembly, a shoulder bolt connects the plates at the bend. At the lower end another double-acting slic pin, this one aluminum, connects the Lever to the Body. The slick pin can be withdrawn into the body to allow swinging the rear plate open for rigging. A plastic block screwed to the front plate between the two shoulder bolts prevents inserting the rope into the wrong place.

- Body: The Body is milled from aluminum alloy and then anodized. It has a U-shaped channel with a cross hole for the slic pin connecting it to the Lever Assembly and a 31 mm. long, 11.5 mm. wide attachment slot angled at 45° to the body axis. A small stainless steel pin in the side of the Body limits how far the Body and Tether can rotate with respect to each other.

- Tender Assembly: The Tender is a small pulley with forged side plates. The arms are 70 mm. long, and the wheel has a U-shaped channel with a 31 mm. major diameter, 25 mm. minor diameter, and 14 mm. internal width. The tender rides on another double-acting aluminum slic pin. This pin also supports the attachment point with a 15 mm by 23 mm. pear-shaped eye.

The front of the Bird is printed with "WLL 140KG." The inside of each plate is printed with a rope illustration showing the rope path and "NO ROPE" where the rope should not go. Each plate has "1," "2," "3," "4," and "5" in raised forged letters indicating the five positions for the adjustable friction bollard. The head of the slic pin has "SLIC PIN" in raised letters.

The left side of the tether is printed with "ROPE RUNNER PRO." The right side is printed with "UP" and a hollow up-pointing arrow. Both sides have "NOTCH" in raised forged letters.

The front plate of the lever assembly is printed with "11 ≤ Ø ≤ 13MM," a human icon, "1X," and "53420" (the model number). The rear plate is printed with "01/21" and "05466." The inside of each plate is printed with a rope illustration showing the rope path.

Both aluminum slic pins have "SLIC," "A," and "PIN" in raised letters on their head.

The inside of each pulley plate is printed with a rope illustration showing the rope path. The attachment point is printed with "ATTACHMENT POINT" and a harness icon.

The Notch Equipment Rope Runner Pro is a refinement of the Singing Tree Rope Runner. The workmanship is excellent. While I see nothing wrong with the original Rope Runner execution, the Rope Runner Pro just looks a lot better.

After taking it out of its box (a very nice box, I must add), I disassembled mine and reassembled it incorrectly. Twice. In other words, it is fairly easy to assemble the Tender Assembly incorrectly by failing to place the pulley opposite the flat face of the tender body. While this is hardly a fatal flaw, it can lead to momentary frustration.

The way the slic pins work allows them to stay within the Rope Runner when opening the device for rigging. While one can remove them and drop parts if one tries hard enough, this would normally not be an issue.

The Rope Runner Pro was designed for arborists, and since I don't swing through trees, I'll let them evaluate it for their applications. For cavers and climbers, it is enough off the mainstream of designs that it doesn't fit in with normal caving ascending techniques, but it is interesting. Overall, I think that it is just a bit too complex and not nearly as efficient as a good eccentric cam ascender.