Technical Details

I acquired my Trango from Jesse Albanese in 2015.

The Trango is 187 mm. tall, 72 mm. wide, 23 mm. thick, and weighs 246 g.

The frame is made by milling an aircraft alloy

extrusion. The extrusion direction is oriented parallel to the

vertical axis of the ascender. The frame contains two opposing

channels. One channel is rounded and becomes the rope channel,

the other is square and holds the cam. The rope channel is 16 mm. wide. Starting with a length

of extrusion, everything that doesn't look like ascender frame

is machined away. In particular, the rope channel is shortened,

the handle hole is cut, two 15.6 mm. sling attachment holes

are drilled at the bottom, a subtriangular hole is milled at the top, the

unused lower portion of the cam channel is cut back, and all the

sharp corners are rounded. My ascender has a blue anodized finish.

The frame is made by milling an aircraft alloy

extrusion. The extrusion direction is oriented parallel to the

vertical axis of the ascender. The frame contains two opposing

channels. One channel is rounded and becomes the rope channel,

the other is square and holds the cam. The rope channel is 16 mm. wide. Starting with a length

of extrusion, everything that doesn't look like ascender frame

is machined away. In particular, the rope channel is shortened,

the handle hole is cut, two 15.6 mm. sling attachment holes

are drilled at the bottom, a subtriangular hole is milled at the top, the

unused lower portion of the cam channel is cut back, and all the

sharp corners are rounded. My ascender has a blue anodized finish.

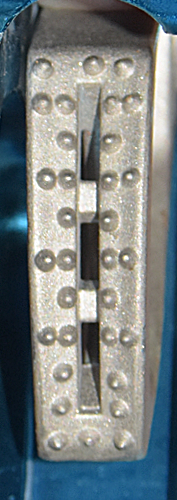

The cam is a skeletonized casting with a (3)(2S2.1S1)^4(1S1)(3)

conical tooth count, where "S" indicates a single relief slot. The cam radius increases from 43 to 58 mm. over an angle of 43°, giving a 22° cam angle. The inner cam face radius reduces from top to bottom of the cam

in order to match different diameter ropes. The cam pivot is a solid 6 mm.

round head rivet. Steel washers separate the rivet heads from the aluminum alloy frame. The cam safety

is an elbow shaped nylon(?) lever mounted on a roll pin in the

cam. A single spring serves as cam spring and safety spring. Normally

this spring holds the safety where it protrudes from both the

top and bottom of the cam. The bottom protrusion interferes with

the shell’s cam channel and prevents opening the cam. When the

top of the lever is pushed towards the cam teeth, the lower protrusion

rotates into a recess in the cam, thus allowing the cam to open.

Below the safety is a hand grip assembly consisting

of two blue plastic pieces pinned to the frame with two

roll pins. The larger piece has three molded finger grooves, and

a road shelf at the bottom to keep the little finger off the

frame. The other piece is a spacer whose sole purpose appears

to be so that the same hand grip molding could be used on both

right and left hand ascenders

The name "TRANGO" is stamped on the front strap.

This ascender closely resembles the C.M.I. UltrAscender, but there are differences, both positive and negative.

The ascender can be operated with either hand. The safety improves the C.M.I. UltrAscender design by replacing the fragile ears with a solid post. Unfortunately, the safety spring is too weak for the cam hold-open feature to work reliably in the full-open position. As for the partially-open position, I do not like cam safeties which can hold a cam partially open.

I can understand holding the cam full open while waiting for your

turn on rope, for example, but partial hold-opens are next to

useless. In fact, they present a potential hazard if the cam does

not close completely when rigging in, particularly if the ascender

is being used as a safety at the pit lip. My philosophy is simple:

if an ascender is on rope, it should be capable of holding weight.

Most situations where a hold-open are useful (e.g., rescue hauling

systems) involve some form of ascender abuse.

The finger grooves on the hand grip are simply too small, and

should be eliminated entirely. I have large hands and find them

uncomfortable.

The cam workmanship is good, but the teeth are short and blunt, making them rather susceptible to mud.

For far more content, use a larger monitor and a full-width window.

Hundreds of cell phone users complained and asked me to for a simpler, mobile friendly site. In particular, they wanted me to limit each page to a small number of pictures and minimize my use of text. This new site provides what they asked for.