Along the way, I developed an interest in metal shapers, and bought a small Atlas 7. I enjoyed watching the Atlas run so much that nine days later, I bought a 20 inch G&E.

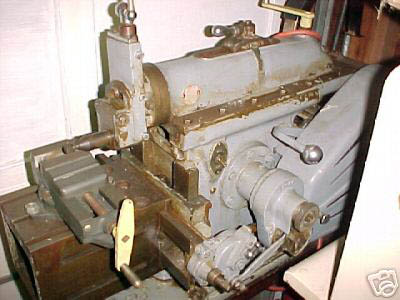

I use the G&E for large roughing jobs that require removing

lots of metal rapidly. Shapers use single point cutting tools that cost far less than and are easier to sharpen than milling cutters, so I don't mind using them on rusted or sand cast surfaces that abrade the tooling. With a 7.5 HP motor, the ram can take

huge cuts. At slow speeds, the ram generates tremendous forces.

I've shattered one-inch tool bits, broken castings, and have nearly sent

the 300 pound vise flying. Huge tan chips come off smoking and quickly

turn blue. The G&E deserves a lot of respect, since it would

crush bones and sever limbs if I ever made a mistake with it.

I use the G&E for large roughing jobs that require removing

lots of metal rapidly. Shapers use single point cutting tools that cost far less than and are easier to sharpen than milling cutters, so I don't mind using them on rusted or sand cast surfaces that abrade the tooling. With a 7.5 HP motor, the ram can take

huge cuts. At slow speeds, the ram generates tremendous forces.

I've shattered one-inch tool bits, broken castings, and have nearly sent

the 300 pound vise flying. Huge tan chips come off smoking and quickly

turn blue. The G&E deserves a lot of respect, since it would

crush bones and sever limbs if I ever made a mistake with it.

The vise is holding a mounting plate that I made to let me

clamp small jobs as if they were on the table, without having

to remove the heavy vise. Each hole is tapped for 1/2-13 UNC.

There are clamps at the shaper end to keep the plate from being

ejected from the vise (these are loose in the photo). Set screws along the edge allow me to create

a precisely level surface for mounting the work piece.

|

|

|

What I like

|

What I dislike

|

Problems

|

Other comments

|

‡Godzilla is King of the Monsters.

I found this shaper, complete with stand, on eBay in May 2005, and I drove to Erie to pick it up in person. My Atlas is one of the original Model 7s, not the later 7B that had a support foot for the table. The hand cranks are not original. When I acquired it, the shaper had an Atlas milling machine vise, not a shaper vise. I bought some castings to make a shaper vise, but never finished the project as other events intervened. In 2007, Tore Bertilsson emailed to me from Örebro, Sweden. He had an extra Atlas shaper vise and was looming for an Atlas milling vise, and was wondering if we could trade. Not only was this a good deal, but I had a business trip scheduled to Västerås, an hour from him. We made arrangements, and despite some confusion, were able to meet in my hotel and make the trade. When I got home, I found the vise in pieces. For reasons beyond my understanding, airport security felt that they needed to disassemble the entire thing.

I found this shaper, complete with stand, on eBay in May 2005, and I drove to Erie to pick it up in person. My Atlas is one of the original Model 7s, not the later 7B that had a support foot for the table. The hand cranks are not original. When I acquired it, the shaper had an Atlas milling machine vise, not a shaper vise. I bought some castings to make a shaper vise, but never finished the project as other events intervened. In 2007, Tore Bertilsson emailed to me from Örebro, Sweden. He had an extra Atlas shaper vise and was looming for an Atlas milling vise, and was wondering if we could trade. Not only was this a good deal, but I had a business trip scheduled to Västerås, an hour from him. We made arrangements, and despite some confusion, were able to meet in my hotel and make the trade. When I got home, I found the vise in pieces. For reasons beyond my understanding, airport security felt that they needed to disassemble the entire thing.

I use the Atlas for small, coarse jobs because

the setup and cleanup time is sometimes faster than for my mill.

What I like

|

What I dislike

|

Problems

|

Other comments

|

‡Minilla (sometimes spelled Minya) is the Son of Godzilla.

![]()